Mineral based water miscible metalworking fluids

Mineral-based water-miscible metalworking fluids are a crucial element in modern machine shops. Read more

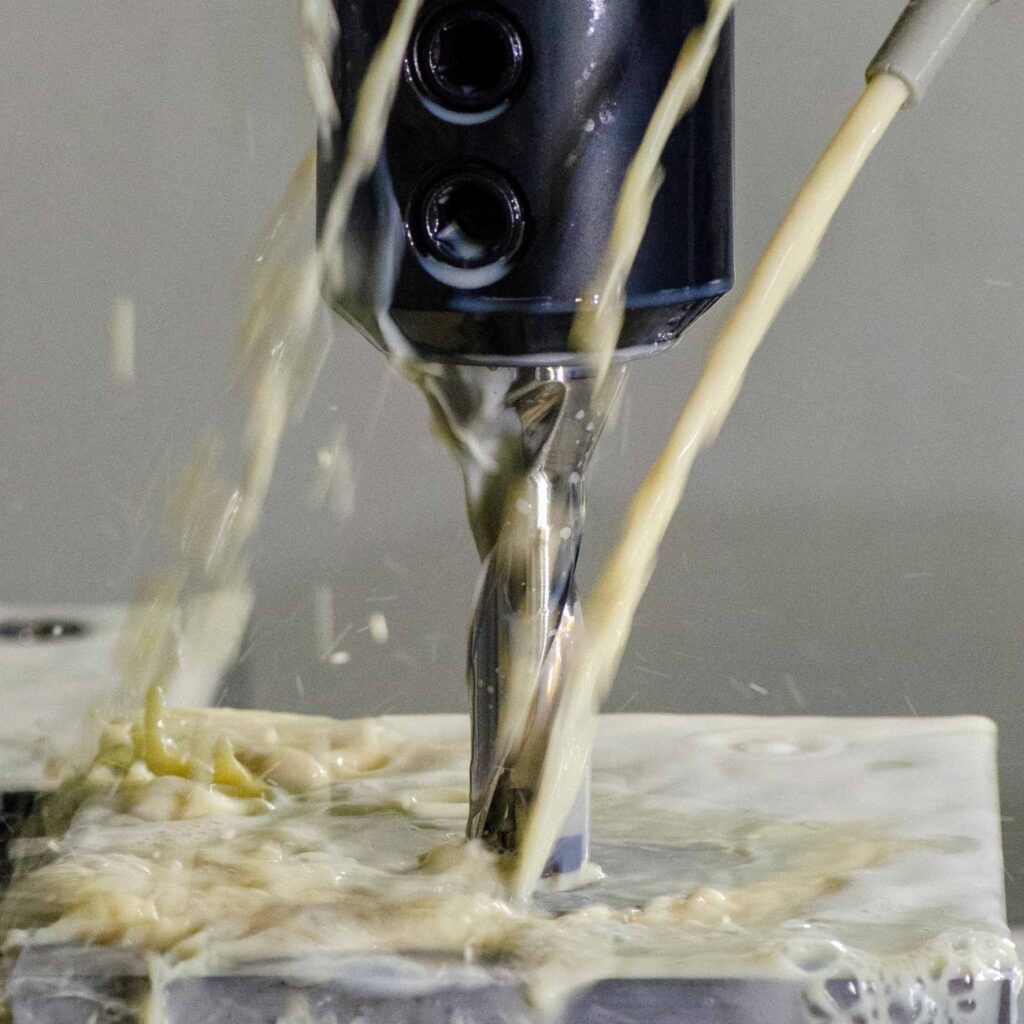

Mineral-based water miscible metalworking fluids are designed

to optimise lubrication and cooling in machining operations. These products offer good chemical stability and excellent heat dissipation capacity.

The easy miscibility in water of these mineral-based metalworking fluids facilitates their handling,

contributing to a cleaner and safer working environment. These coolants reduce operating costs due to their durability and efficiency, minimising the formation of harmful mists and ensuring optimal thermal control during machining. .

These fluids, essential for the proper functioning of machine tools, offer a number of benefits that go far beyond simple lubrication. In this talk, we will explore in detail what mineral-based water-miscible metalworking fluids are, how they are used, what benefits they bring, and answer frequently asked questions on this topic.

Understanding Mineral-Based Water-Miscible Metalworking Fluids

Mineral-based water-miscible metalworking fluids are fluids mainly used in machining to reduce friction and heat generated during the cutting or machining process. These fluids are composed of mineral oils that, when mixed with water, form a stable emulsion. Their cooling and lubricating capacity is essential to ensure the precision and durability of tools, as well as improving the quality of the machined surface.

Main Functions and Advantages of Metalworking Fluids

The use of mineral-based water-miscible metalworking fluids offers numerous advantages. Firstly, their cooling capacity helps to prevent tools and workpieces from overheating, reducing the risk of thermal deformation. In addition, the lubrication provided by these fluids decreases friction between the tool and the material, prolonging tool life and improving the surface finish of the workpiece.

Another significant advantage is the reduction in tool wear. Due to their composition, mineral-based water-miscible metalworking fluids form a protective film that minimises direct contact between metal surfaces, thus reducing wear and increasing the efficiency of the production process.

Applications in machine shops

In machine shops, mineral-based water-miscible metalworking fluids are used in a wide range of processes, including turning, milling, drilling and grinding. Their versatility makes them suitable for different types of materials, from ferrous to non-ferrous metals, ensuring optimal performance every time.

The correct use of these fluids requires careful management of concentrations and operating conditions. It is essential to regularly monitor the emulsion concentration to ensure that it remains within optimal limits, thus guaranteeing maximum efficiency and safety during processing operations.

Environmental and safety benefits

In addition to operational benefits, mineral-based water-miscible metalworking fluids also offer environmental advantages. Being water miscible, these fluids are generally less polluting than pure oils, reducing the environmental impact of machining operations. In addition, their formulation is often designed to be less irritating to the skin, improving working conditions for operators.

Frequently asked questions about mineral-based water-miscible metalworking fluids

1. What is the ideal concentration for the use of water-miscible metalworking fluids?

The ideal concentration depends on the type of work and the material being processed. In general, a concentration between 5% and 10% is recommended, but it is important to follow the manufacturer's instructions and to monitor the concentration regularly.

2. How can the service life of a metalworking fluid be extended?

In order to prolong the service life of a metalworking fluid, it is essential to keep the lubrication system clean, avoid contamination and regularly monitor the concentration and pH of the emulsion.

3. What are the signs of a degraded metalworking fluid?

Signs of a degraded metalworking fluid include an unpleasant odour, a change in colour, foaming and a reduction in cooling and lubrication performance.

Conclusions

Mineral-based water-miscible metalworking fluids are an essential component for machine shops, offering significant benefits in terms of efficiency, quality and safety. Their correct handling and use can lead to substantial improvements in production processes, reducing operating costs and environmental impact. With a thorough understanding of their characteristics and applications, workshops can optimise their operations and ensure high quality results.