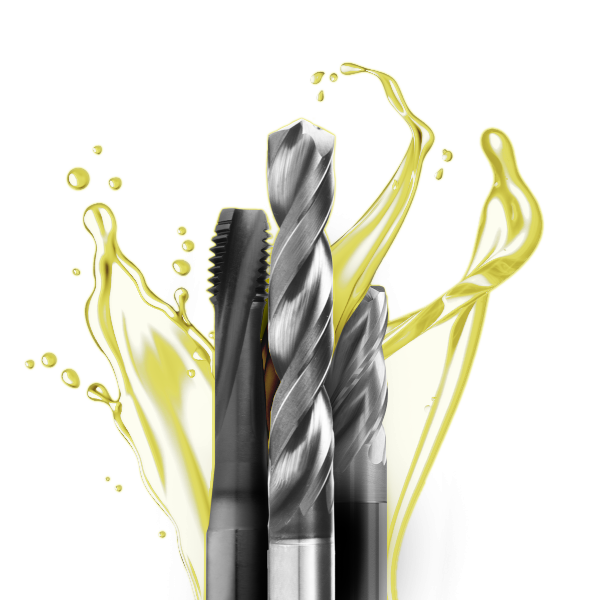

Mineral and ester based water miscible metalworking fluids

Mineral and ester-based water-miscible metalworking fluids are a crucial element in the modern machine shop landscape. Read more

Water miscible mineral- and ester-based metalworking fluids combine

the hydrolytic stability of mineral oil with the high lubricity of ester bases. This synergy offers excellent wear protection, effective cooling and reduced chemical risk, improving workshop safety.

Due to their easy miscibility in water, these metalworking fluids

are simple to use and manage, reducing mist formation and improving air quality in the workplace. The combined use of mineral and ester bases ensures smooth operation and a safer environment, minimising downtime and maintenance costs.

These fluids, essential for the proper functioning of machine tools, offer a number of benefits that go far beyond simple lubrication. In this in-depth look, we will explore in detail what water-miscible metalworking fluids are, how they are used, the benefits they bring, and answer frequently asked questions on this topic.

Understanding water-miscible metalworking fluids

Water-miscible metalworking fluids are fluids designed to be mixed with water, creating a solution that combines lubricating and cooling properties. These fluids are mainly composed of mineral oils or esters, which are emulsified in water to form a stable mixture. The choice between mineral and ester-based depends on the specific operational requirements and desired characteristics of the fluid.

Primary Functions of Metalworking Fluids

The primary function of metalworking fluids is to reduce friction between cutting tools and machined workpieces, minimising tool wear and improving the surface quality of the finished workpiece. In addition, these fluids play a key role in cooling, dissipating the heat generated during cutting operations and preventing overheating of machines and machined materials.

Advantages of using water-miscible metalworking fluids

The use of water-miscible metalworking fluids offers several advantages. First of all, their cooling capacity is superior to pure lubricants due to the presence of water, which absorbs and dissipates heat more efficiently. This translates into longer tool life and reduced maintenance downtime.

In addition, water-miscible metalworking fluids are generally safer for the environment than pure oil-based lubricants, as they contain fewer potentially harmful chemicals. Their formulation also allows for better biodegradability, reducing environmental impact.

Applications in machine shops

In machine shops, water-miscible metalworking fluids are used in a wide range of applications, including turning, milling, drilling and grinding. Their versatility makes them suitable for various materials, from ferrous and non-ferrous metals to special alloys. Choosing the right metalworking fluid depends on the specific requirements of the machining process and the characteristics of the material being machined.

Considerations when Choosing a Metalworking Fluid

When choosing a water-miscible metalworking fluid, it is important to consider several factors. Compatibility with the materials being machined, operating conditions and environmental regulations are just some of the variables to be considered. In addition, emulsion stability, corrosion resistance and the ability to prevent foaming are essential characteristics for optimal performance.

Frequently Asked Questions about water-miscible metalworking fluids

1. What is the difference between mineral and ester-based metalworking fluids?

Mineral-based metalworking fluids are derived from petroleum and offer good lubricating and cooling properties. Ester-based, on the other hand, are synthetic and offer better biodegradability and superior performance in terms of thermal stability and oxidation resistance.

2. How is a metalworking fluid mixture prepared?

The preparation of a metalworking fluid mixture requires diluting the concentrate in water according to the manufacturer's specifications. It is important to use good quality water to avoid emulsion stability problems.

3. What are the signs of an unstable emulsion?

An unstable emulsion can manifest itself by excessive foaming, phase separation or colour changes. These signs indicate the need to check the concentration of the metalworking fluid and the quality of the water used.

4. How should used metalworking fluids be disposed of?

Used metalworking fluids must be disposed of according to local hazardous waste regulations. It is important to cooperate with companies specialised in the treatment and disposal of these fluids to ensure compliance with environmental laws.

Conclusions

Mineral and ester-based water-miscible metalworking fluids are essential components for machine shops, offering significant benefits in terms of performance, safety and environmental sustainability. Their proper selection and management can greatly improve operational efficiency and the quality of finished products. With a thorough understanding of their characteristics and applications, workshops can optimise machining processes and reduce operating costs, contributing to the company's overall success.