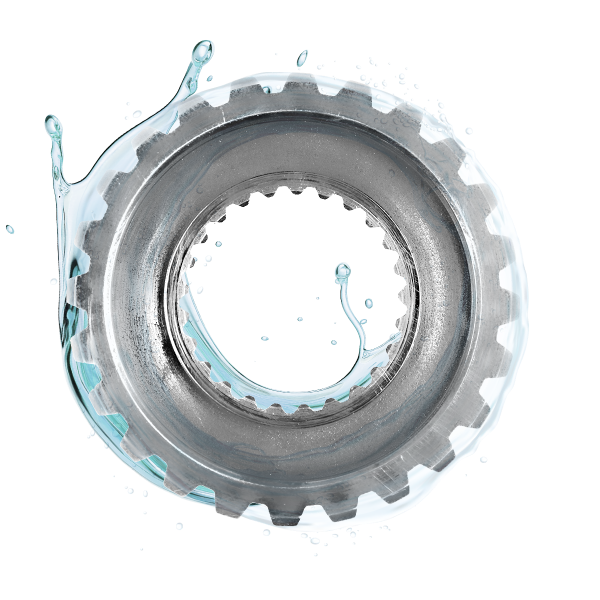

Degreasing fluids

Degreasing fluids: an indispensable ally in machine shops

In the world of machine shops, efficiency and cleanliness are key elements in ensuring optimal operation of equipment and machinery. Read more

-

Degreasing fluid Safesolv LANDOIL

Safesolv LANDOIL degreasing fluid offers excellent protection, is easy to apply and has excellent cleaning power. -

Degreasing fluid Solv LANDOIL

Solv LANDOIL degreasing fluid guarantees maximum electrode life, high cooling power and exceptional visibility of the workpiece.

Degreasing fluids are formulated to effectively remove oils, grease and residues from metal and mechanical surfaces.

These fluids penetrate impurities, dissolving them quickly without damaging the treated materials. Used in industrial environments, they provide deep and safe cleaning, improving equipment efficiency.

Thanks to their composition, degreasing fluids guarantee excellent results even in difficult conditions

such as in the presence of stubborn dirt or in areas with accumulated residues. Their effectiveness helps keep operating surfaces in optimum condition, reducing the risk of wear and tear and increasing the safety of machines and operators.

Degreasing fluids are an essential solution for maintaining these high standards, offering deep and safe cleaning of metal surfaces and mechanical components. In this in-depth look, we will explore in detail what degreasing fluids are, how they are used, their benefits and answer some of the most frequently asked questions on this topic.

What are degreasing fluids?

Degreasing fluids are chemical compounds designed to remove grease, oil, dirt and other contaminants from metal surfaces and mechanical equipment. These products are formulated to dissolve and disperse oily residues, making it easier to clean and maintain surfaces. Degreasing fluids can be water- or solvent-based, each with specific characteristics that make them suitable for different applications.

Types of degreasing fluids

There are different types of degreasing fluids, each with unique properties that make them suitable for specific cleaning needs. Water-based degreasing fluids are generally less aggressive and more environmentally friendly, ideal for cleaning delicate surfaces or applications where environmental safety is a priority. In contrast, solvent-based degreasing fluids are more powerful and suitable for removing heavy greases and oils, but require additional precautions for safety and waste management.

Use of degreasing fluids in machine shops

In machine shops, degreasing fluids are used for a wide range of applications. From cleaning engines and mechanical components to maintaining equipment and work surfaces, these products are essential to ensure that operations run smoothly. Degreasing fluids can be applied by dipping, spraying or manual cleaning, depending on the specific needs and equipment available.

Advantages of using degreasing fluids

The use of degreasing fluids offers numerous advantages in mechanical workshops. Firstly, they improve operating efficiency by reducing the build-up of grease and dirt that can affect the operation of equipment. They also help to prolong the life of machinery by preventing corrosion and premature wear. Degreasing fluids also help maintain a safer working environment by reducing the risk of accidents caused by slippery surfaces or malfunctioning equipment.

Frequently asked questions about degreasing fluids

1. What is the difference between water- and solvent-based degreasing fluids?

Water-based degreasing fluids are less aggressive and more environmentally friendly, ideal for delicate surfaces. Solvent-based ones are more powerful and suitable for removing heavy grease, but require safety precautions.

2. How do I choose the right degreasing fluid for my workshop?

The choice of degreasing fluid depends on the type of contaminant to be removed, the material of the surface to be cleaned and environmental and safety considerations.

3. Can degreasing fluids damage metal surfaces?

When used correctly, degreasing fluids will not damage metal surfaces. It is important to follow the manufacturer's instructions and choose the correct product for the type of surface.

4. Can degreasing fluids be used on painted surfaces?

Some degreasing fluids can be used on painted surfaces, but it is essential to check the compatibility of the product with the type of paint to avoid damage.

5. How should used degreasing fluids be disposed of properly?

Used degreasing fluids must be disposed of according to local hazardous waste regulations. It is important to follow guidelines to ensure environmental safety.

Conclusions

Degreasing fluids are indispensable tools in machine shops, offering effective solutions for cleaning and maintaining equipment. Choosing the right product and using it correctly are key to maximising the benefits and ensuring a safe and efficient working environment. With a thorough understanding of their characteristics and applications, workshops can optimise their operations and extend the life of their machinery.