Water miscible metalworking fluids

Water miscible metalworking fluids: Efficient Solutions for Mechanical Workshops

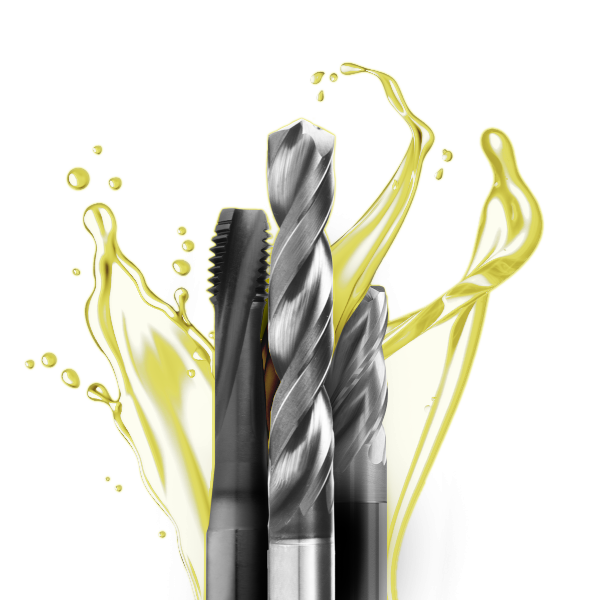

In the world of machining, the choice of the right coolant is crucial to ensuring both the longevity of cutting tools and the precision of machining operations. Read more

Water miscible cooling lubricants are fluids

designed to combine the cooling properties of water with effective lubrication in machining operations. These products improve heat dissipation, reduce tool wear and increase precision, contributing to a safer working environment.

The use of Landoil water miscible cooling lubricants offers advantages for the operator and the environment.

They are manufactured with a highly safe formulation, minimising risks to operator health and the environment. By maintaining stable temperatures and reducing friction, these fluids also extend tool life and improve the efficiency of production processes.

Among the various options available, water miscible metalworking fluids stand out for their ability to provide a balance between cooling and lubrication. These fluids, mixed with water, are essential for efficient heat dissipation and optimal performance in numerous mechanical applications. But what exactly are water miscible metalworking fluids, and how can they benefit your workshop?

What Are Water Miscible Metalworking Fluids?

Water miscible metalworking fluids, also known as emulsifiable coolants, are lubricating fluids that can be mixed with water to form a stable emulsion. These coolants are primarily used in metalworking processes to reduce friction, lower temperatures, and ensure smooth operations. The water component in the mixture helps cool the tool and the workpiece, while the oil or synthetic component provides the necessary lubrication.

The main advantage of water miscible metalworking fluids is their superior cooling capacity, which prevents overheating during high-speed machining and extends the life of the cutting tool. Additionally, they are widely used in operations that require machining of various metals, ensuring reliable performance across a range of applications.

Advantages of Water Miscible Metalworking Fluids

Using water miscible metalworking fluids offers numerous benefits in mechanical workshops, improving operational efficiency and the quality of work. Here are some of the key advantages:

Efficient Cooling: Thanks to the water component in the mixture, these fluids offer quick and effective cooling, preventing overheating of both the tools and the workpiece.

Better Lubrication: The oil component in the coolant ensures optimal lubrication, reducing friction between the tool and the material being worked, and improving the surface finish.

Extended Tool Life: By reducing wear due to heat and friction, these coolants help extend the life of cutting tools, lowering replacement costs.

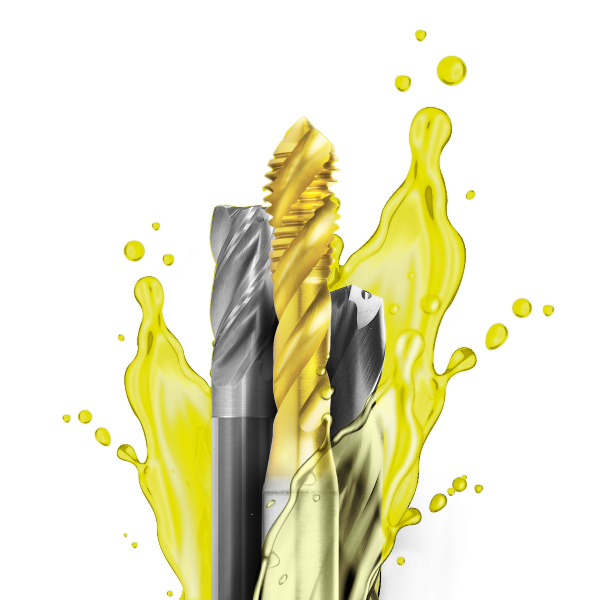

Versatility in Use: Water miscible metalworking fluids are suitable for a wide range of applications, from milling and turning to drilling, offering flexible solutions for different mechanical needs.

Water Miscible Metalworking Fluids for Metal

In metalworking operations, water miscible metalworking fluids for metal play a crucial role in ensuring precision and reliability. Their ability to quickly cool the cutting tool and workpiece reduces the risk of deformation and dimensional errors, providing more stable and accurate machining. These fluids are particularly useful in processing difficult materials like stainless steel and aluminum alloys, where heat generation can be significant.

Best Miscible Metalworking Fluids

The best Miscible Metalworking Fluids are formulated to offer an optimal balance between cooling and lubrication. Their composition allows them to form a stable emulsion with water, ensuring that the fluid retains its properties even in intense machining conditions. These coolants are ideal for a wide range of machine tools, from milling machines to lathes, and can be used in different mixing ratios depending on operational needs.

High-Efficiency Water Miscible Metalworking Fluids for Lathes

High-efficiency water miscible metalworking fluids for lathes are designed to ensure superior performance in high-speed operations where heat generation could compromise the quality of the work. These fluids help maintain controlled temperatures, ensuring consistent lubrication and reducing tool wear. The use of emulsifiable coolants in lathes is essential for improving the surface finish of the workpiece and preventing thermal deformation, especially in prolonged machining operations.

Emulsifiable Coolants for Machine Tools

Machine tools used in workshops require coolants that not only provide efficient cooling but also offer adequate protection against wear and corrosion. Emulsifiable coolants for machine tools ensure continuous and uniform lubrication, reducing the risk of mechanical failure and improving productivity. Using high-quality coolants helps keep machines in optimal condition, extending their lifespan and reducing the need for frequent maintenance.

Water Miscible Metalworking Fluids for Milling

Milling is a machining process that requires a high level of precision and control, especially when working with hard metals. Water miscible metalworking fluids for milling offer rapid cooling and effective lubrication, ensuring that milling tools can operate at high speeds without compromising work quality. Additionally, these fluids contribute to improving the surface finish of the machined part and reducing downtime due to tool replacements.

How to Choose the Right Water Miscible Metalworking Fluid

Choosing the right water miscible metalworking fluid can significantly affect the efficiency of your workshop and the quality of machining operations. Here are some factors to consider when selecting the right product:

Type of Material Being Machined: The nature of the material being worked on influences the choice of coolant. For example, harder materials require greater cooling capacity, while softer materials may need better lubrication.

Operating Conditions: If your operations involve high speeds or extended durations, it’s important to choose a high-efficiency coolant that can maintain emulsion stability under intense working conditions.

Machine Compatibility: Some machine tools require specific coolant formulations to ensure optimal performance and reduce wear on mechanical components.

Frequently Asked Questions About Water Miscible Metalworking Fluids

1. What are the main advantages of water miscible metalworking fluids compared to neat oils?

Water miscible metalworking fluids offer superior cooling due to the presence of water, making them ideal for high-speed operations. However, compared to neat oils, they offer slightly less lubrication.

2. Can water miscible metalworking fluids be used on any machine tool?

Yes, water miscible metalworking fluids are suitable for a wide range of machine tools, as long as the appropriate formulation is selected for the specific operations.

3. How can I ensure that the coolant mixture remains stable over time?

To maintain emulsion stability, it’s important to regularly monitor the oil-to-water mixing ratio and use proper equipment for maintaining fluid quality.

Conclusion

Water miscible metalworking fluids are essential tools for mechanical workshops looking to optimize machining operations, extend tool life, and ensure high-quality finishes on machined parts. Choosing the right coolant for your application will not only improve efficiency but also reduce long-term operational costs. With proper management and maintenance, water miscible metalworking fluids can deliver superior performance across a wide range of mechanical operations.