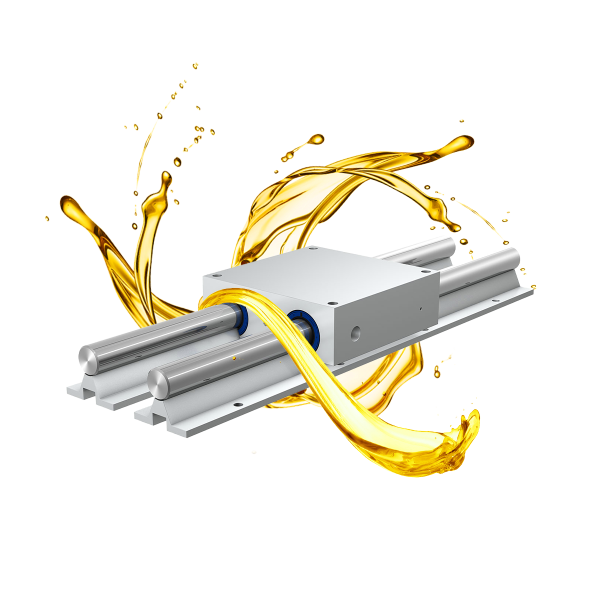

Slideway oils

In the world of machine shops, efficiency and precision are key elements in ensuring quality work and customer satisfaction. Read more

Guide and slide oils are lubricants specifically for the sliding surfaces of machine tools, such as guides and slides.

These oils offer excellent anti-stick-slip properties, reducing friction and ensuring smooth and precise movements. They also improve wear protection, prolonging the service life of machines.

Designed to withstand the toughest working conditions, guide and slide oils ensure stable lubrication even at high loads and low speeds.

The use of these oils not only improves operational efficiency, but also contributes to a safe working environment by reducing the risk of malfunctions and failures.

Among the various components that help achieve these goals, slide and slide oils play a crucial role. These specialised lubricants are designed to reduce friction and wear between moving surfaces, thereby improving the performance of machine tools and extending their service life.

Understanding slide and guideway oils

Guide and slide oils are lubricants specifically formulated for use on sliding surfaces, such as those found in machine tools. These surfaces, often made of metal, require adequate lubrication to prevent premature wear and ensure smooth and precise movement. Guide and slide oils are designed to adhere firmly to surfaces, forming a protective film that reduces friction and prevents corrosion.

Primary functions of slide and slide oils

The primary function of slide and carriage oils is to reduce friction between moving surfaces. This not only improves the operating efficiency of machines, but also helps to reduce energy consumption. In addition, these oils help dissipate the heat generated by friction, preventing components from overheating and reducing the risk of mechanical failure.

Another important function is protection against corrosion. Metal surfaces are prone to oxidation and corrosion, especially in humid environments or in the presence of aggressive chemicals. Guide and slide oils form a protective barrier that prevents direct contact between the metal and corrosive agents, thus prolonging the life of the components.

Advantages of using slide and slide oils

The use of slide and carriage oils offers machine shops numerous advantages. First of all, it improves the precision of machine tools. A smooth and controlled movement of the sliding surfaces is essential to ensure the precision of machining operations, minimising errors and production waste.

In addition, the use of appropriate oils reduces maintenance costs. Well-lubricated machines require less maintenance and have a longer service life, thus reducing overall operating costs. This translates into increased productivity and profitability for the workshop.

Selecting the right oil for guides and slides

Selecting the right oil for guides and slides depends on several factors, including the type of machine, operating conditions and the specific requirements of the application. It is important to consider the viscosity of the oil, which must be adequate to ensure effective lubrication without compromising surface movement.

In addition, it is essential to evaluate the compatibility of the oil with the sliding surface materials and other lubricants used in the machine. Some oils may contain special additives to improve performance under extreme conditions, such as high temperatures or high loads.

Frequently asked questions about guide and slide oils

1. What is the difference between a slide and slide oil and an engine oil?

Guide and slide oils are specifically formulated to reduce friction between sliding surfaces, whereas motor oils are designed to lubricate the moving parts inside an engine. Guide and slide oils have a different viscosity and chemical composition to meet the specific needs of sliding surfaces.

2. How often should I change the guide and slide oil?

The frequency of replacement depends on the operating conditions and the type of machine. In general, it is advisable to follow the machine manufacturer's recommendations and regularly monitor the state of the oil to ensure optimal lubrication.

3. Can I use the same oil for all the machines in my workshop?

Not necessarily. It is important to select the right oil for each machine according to its specific needs and operating conditions. Using an unsuitable oil can compromise the machine's performance and reduce its service life.

Conclusions

Guide and slide oils are essential components for the efficient and precise operation of machine tools in machine shops. Their ability to reduce friction, protect against corrosion and improve machining precision makes them indispensable for ensuring quality and productivity. Selecting the right oil and using it correctly can make the difference between a workshop operating at full capacity and one that faces frequent maintenance problems and inefficiencies. Investing in the right lubrication is a critical step for the long-term success of any mechanic's business.