Refrigerants

Coolants are essential components in the machine shop sector, where precision and operational efficiency are paramount. Read more

-

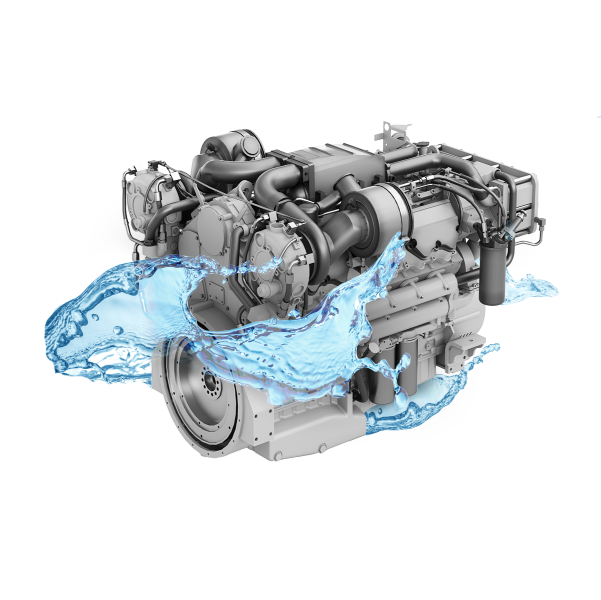

Refrigerant fluid Antifrost BLUE ECO LANDOIL

Coolant fluid for passenger car, commercial vehicle and bus engines with iron or aluminium radiators, excellent toxicological profile. -

Refrigerant fluid Antifrost BLUE LANDOIL

Coolant fluid for passenger car, commercial vehicle and bus engines with an iron or aluminium radiator, ensuring efficiency and protection.

Coolant fluids are essential for dissipating the heat generated during machining, keeping temperatures under control.

These fluids improve operational stability and protect machine tool components from thermal wear, ensuring longer tool life and safer, more precise machining.

Designed to operate in high and very low temperature conditions, coolants offer excellent heat transfer capability

and prevent components from overheating. Using the right coolants not only improves energy efficiency, but also contributes to a safe working environment by reducing the risk of malfunctions.

These fluids play a crucial role in maintaining optimal machine temperatures, thus ensuring their smooth operation and extending their service life. In this in-depth look, we will explore in detail what coolants are, how they are used, their benefits and answer some of the most frequently asked questions on this topic.

Understanding refrigerants

Refrigerants, also known as cooling fluids, are substances used to reduce and maintain the temperature of a mechanical system. These fluids are designed to absorb the heat generated during machine operation and dissipate it effectively, preventing overheating and ensuring that equipment operates efficiently.

Operation and applications

In the machine shop context, refrigerants are used in a variety of applications, including machine tools, industrial air conditioning systems and production plants. Their ability to transfer heat makes them ideal for maintaining operating temperatures within safe limits, reducing the risk of mechanical failure and improving the quality of the end product.

Advantages of using refrigerants

The use of refrigerants offers numerous advantages. Firstly, they help improve the energy efficiency of machines, reducing the energy consumption required to maintain operating temperatures. They also prolong the life of equipment, reducing wear and tear and the risk of damage caused by excessive heat. Finally, they improve operational safety by preventing overheating that could lead to dangerous situations.

Types of refrigerants

There are different types of refrigerants, each with specific characteristics that make them suitable for particular applications. Among the most common are fluids based on water, ethylene glycol and mineral oils. The choice of the most suitable refrigerant fluid depends on various factors, including operating temperature, compatibility with equipment materials and environmental regulations.

Frequently asked questions about refrigerants

1. What is the difference between a refrigerant and a lubricant?

Refrigerants are designed to absorb and dissipate heat, while lubricants reduce friction between moving surfaces. Although both can be used in combination, they perform distinct functions.

2. How do I choose the right coolant for a specific application?

The choice of refrigerant depends on various factors, including operating temperature, compatibility with equipment materials and environmental regulations. It is important to consult the manufacturer's specifications and, if necessary, an expert in the field.

3. What are the signs of an ineffective refrigerant?

An ineffective refrigerant fluid can manifest itself through increased operating temperature, reduced energy efficiency and increased equipment wear. It is important to regularly monitor the performance of the fluid and replace it when necessary.

Conclusions

Refrigerants are essential components for the efficient and safe operation of machines in machine shops. Their ability to maintain operating temperatures within safe limits not only improves energy efficiency, but also extends equipment life and improves operational safety. Choosing the right coolant and regularly monitoring its performance is crucial to ensure successful mechanical operations.