Protectants fluids

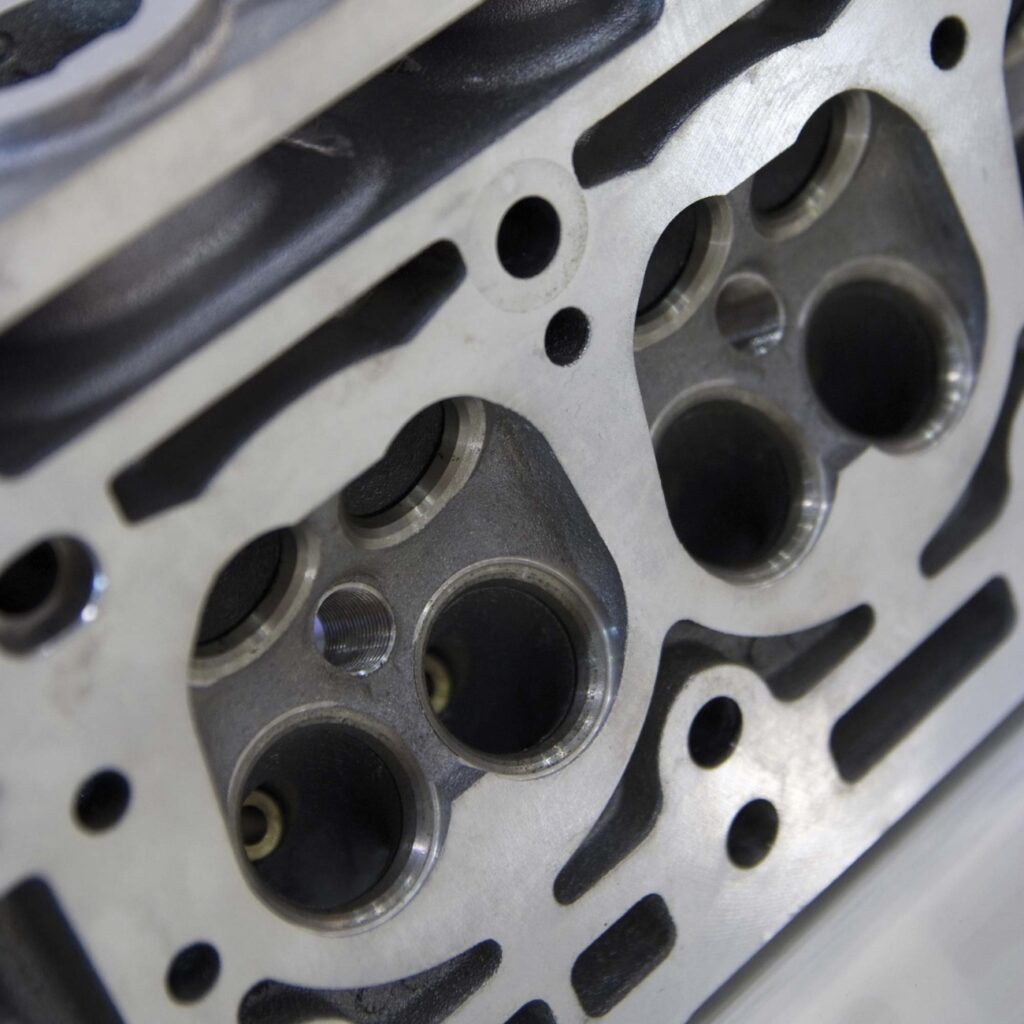

Protective fluids: essential for machine shop efficiency

In the world of machine shops, the efficiency and longevity of equipment is crucial to ensure smooth and uninterrupted operations. Read more

-

Protective fluid Protex DW/O LANDOIL

Protex DW/O LANDOIL protective fluid offers protection for up to 12 months, is easily applied and removed for simple and effective maintenance. -

Protective fluid Protex DW/O VOC Free LANDOIL

LANDOIL's protective fluid Protex DW/O VOC Free LANDOIL offers protection for up to 8 months, ideal even under harsh conditions, VOC-free for optimal safety. -

Protective fluid Protex DW/O VOC Free Plus LANDOIL

LANDOIL's protective fluid Protex DW/O VOC Free Plus offers protection for up to 12 months, ideal even under very harsh conditions, VOC-free. -

Protective fluid Protex O LANDOIL

Protex O LANDOIL protective fluid, protection for more than 12 months, easy to apply, versatile for shipping and storage. -

Protective fluid Protex W LANDOIL

Protex W LANDOIL protective fluid offers protection for more than 12 months even in saline atmospheres, easily applied and removed.

Protective fluids are formulated to protect metal surfaces and mechanical components from corrosion, oxidation and staining.

These fluids create a protective barrier that repels moisture and contaminants, ensuring long material life and reducing maintenance time and costs, with an eye on operational safety.

Ideal for industrial applications and component storage, the protective fluids offer long-lasting protection

even in harsh environmental conditions. Their advanced formulation ensures that surfaces remain undamaged and rust-free, improving the reliability and safety of equipment and limiting the risk of damage and downtime.

Protective fluids play a crucial role in this context, offering essential protection against corrosion, wear and tear and other damage that can compromise machine performance. In this in-depth look, we will explore in detail what protective fluids are, what they are used for, how they are used and what benefits they offer, also answering frequently asked questions on this topic.

What are protective fluids?

Protective fluids are chemicals designed to form a protective barrier on metal surfaces and other machine components. These fluids can be oil-, water- or solvent-based and are formulated to prevent corrosion, reduce friction and improve equipment life. Their composition varies depending on the specific needs of the application, but generally include corrosion inhibitors, antioxidant agents and lubricant additives.

What are protective fluids used for?

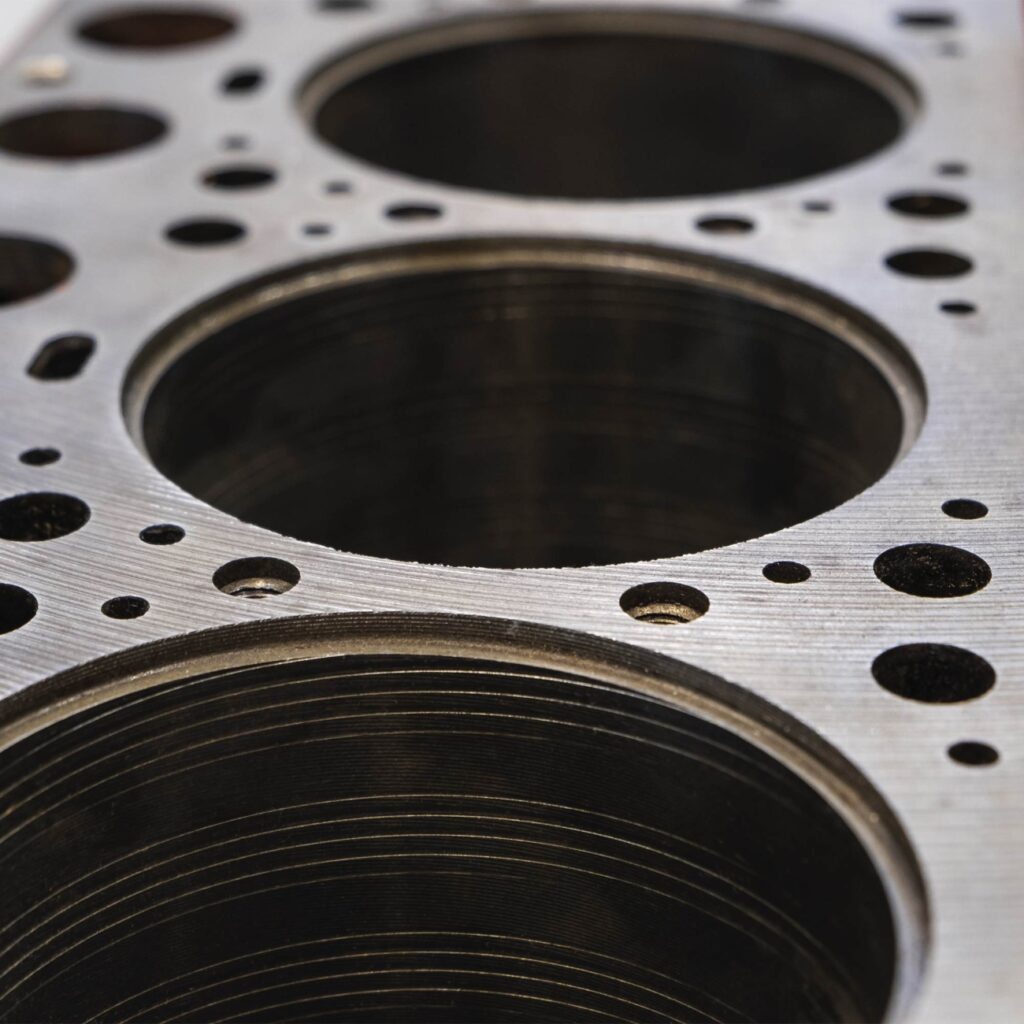

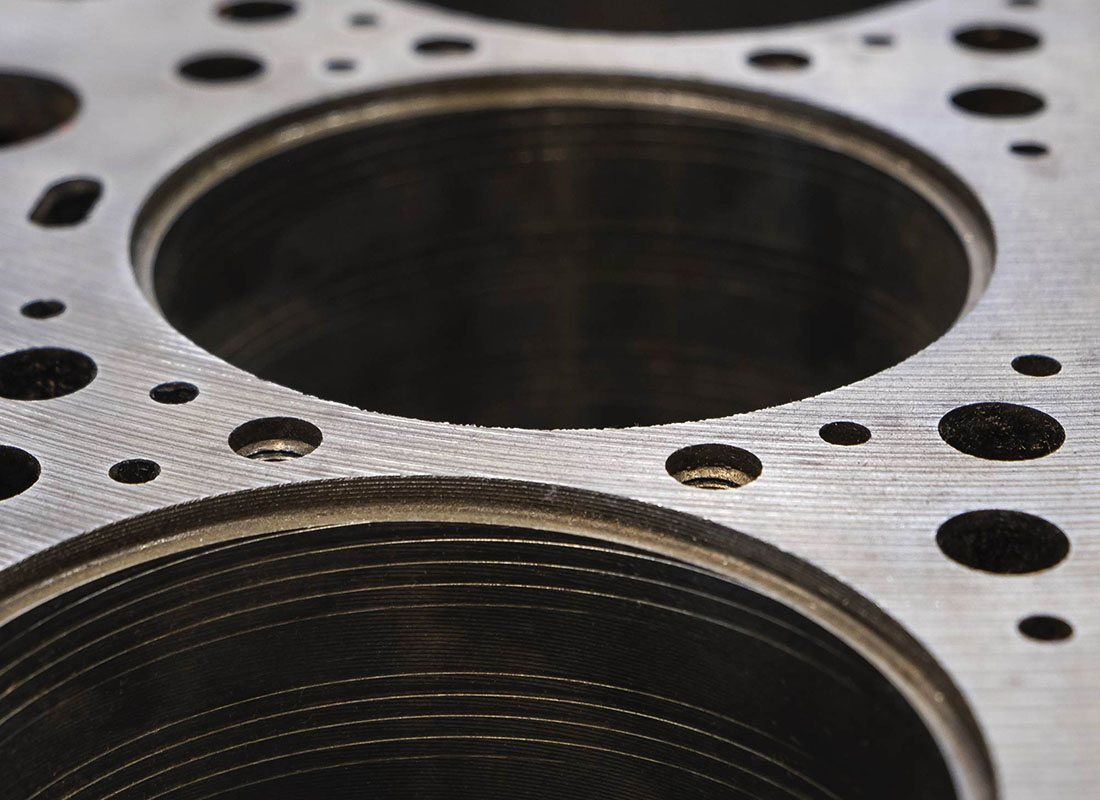

The main use of protective fluids is to protect metal surfaces from corrosion and wear. In a machine shop environment, where machines are exposed to harsh conditions such as humidity, temperature extremes and contaminants, protective fluids are essential to keep equipment in optimal condition. In addition to corrosion protection, these fluids help reduce friction between moving parts, improving operating efficiency and reducing energy consumption.

How are protective fluids used?

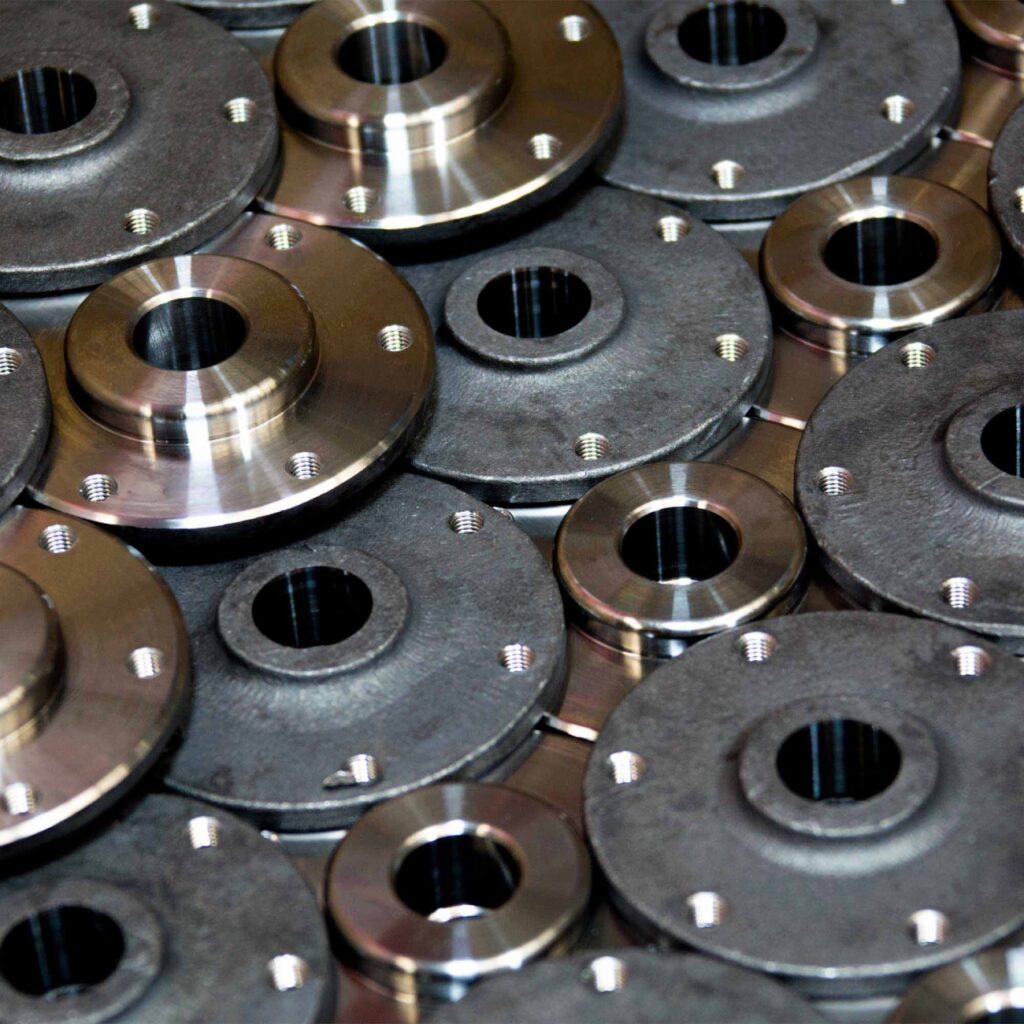

The application of protective fluids varies depending on the type of fluid and the equipment to be protected. In general, fluids can be applied by spraying, dipping or brushing. It is important to follow the manufacturer's instructions to ensure uniform coverage and effective protection. In addition, the frequency of application depends on the operating conditions and the environment in which the machines operate. In particularly aggressive environments, it may be necessary to apply protective fluids more frequently.

Advantages of using protective fluids

The use of protective fluids offers numerous advantages for machine shops. Firstly, they protect equipment against corrosion, prolonging the life of machines and reducing maintenance and replacement costs. They also improve operating efficiency by reducing friction and wear, which translates into lower energy consumption and higher productivity. Protective fluids can also help improve workplace safety by reducing the risk of mechanical failure and accidents.

Frequently asked questions about protective fluids

1. What is the difference between oil-based and water-based protective fluids?

Oil-based protective fluids offer longer-lasting protection and are ideal for applications where machines are exposed to extreme conditions. Water-based fluids, on the other hand, are more environmentally friendly and easy to clean, but may require more frequent applications.

2. Can protective fluids be used on all types of metals?

Most protective fluids are formulated to be compatible with a wide range of metals, but it is important to check the product specification to ensure that it is suitable for the type of metal being protected.

3. How often should protective fluids be applied?

The frequency of application depends on operating conditions and the environment. In general, it is advisable to apply protective fluids regularly to ensure continuous protection.

4. Can protective fluids affect machine performance?

When applied correctly, protective fluids improve machine performance by reducing friction and wear. However, over- or misapplication may adversely affect performance.

5. Can protective fluids be used in combination with other chemicals?

It is important to consult the manufacturer's instructions to determine the compatibility of protective fluids with other chemicals. In some cases, combined use may reduce the effectiveness of the protective fluid.

Conclusion

Protective fluids are an essential component in the maintenance and efficiency of equipment in machine shops. They offer indispensable protection against corrosion and wear, improving the life and performance of machines. Understanding the characteristics and benefits of protective fluids enables workshops to optimise their operations and reduce maintenance costs, while ensuring a safer and more productive working environment. Investing in the right protective fluids is a strategic decision that can lead to significant long-term benefits for any machine shop.