The Landoil plant is now one of the most innovative European production sites in the world of cooling lubricants.

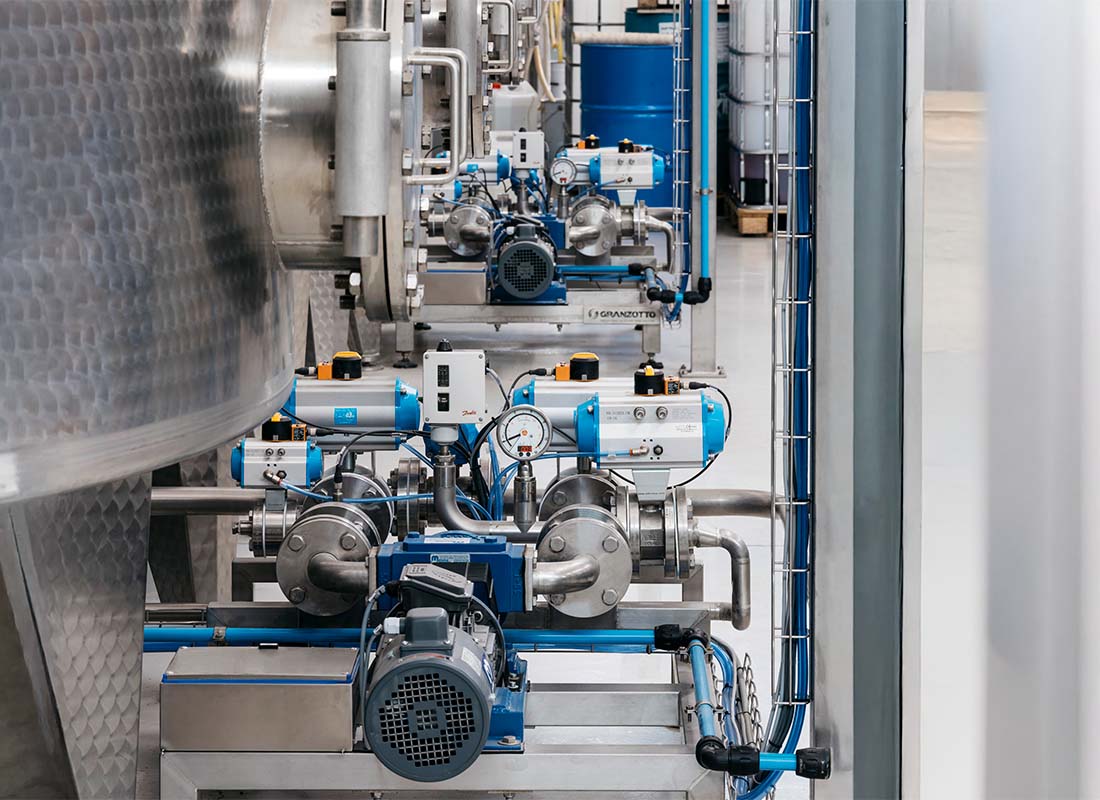

Landoil Technology’s entry into Group A+B has enabled the company to improve its entire production process. With the aim of creating a modern plant that embraces technology, innovation and high-level automation, the Landoil production site is among the most technologically advanced on the market. All stages, from mixing to packaging of cooling lubricants, are managed by software that provides precise control over all operations carried out.

Landoil products fully express the concepts of innovation, technology and safety for the customer. In fact, in addition to improving operational efficiency, there is in our DNA a form of responsibility with respect to issues such as the elimination of risks for operators who are in contact with lubricants on a daily basis and environmental protection. Having to meet multiple needs, we are able to produce and store our products in any format: from 5 litre canisters to 200 litre drums or 1000 litre IBCs.

We formulate, test, produce and distribute over 70 product lines. This 360° level of control allows us to carefully select the raw materials, innovate to constantly improve the formulations of cooling lubricants, optimise the production processes and ancillary services, obtaining a product of absolute quality as the final result.