Polymer-based lubricants

Polymer-based lubricants represent one of the most significant innovations in the field of industrial lubrication, offering advanced solutions for machine shops seeking to optimise the performance of their equipment. Read more

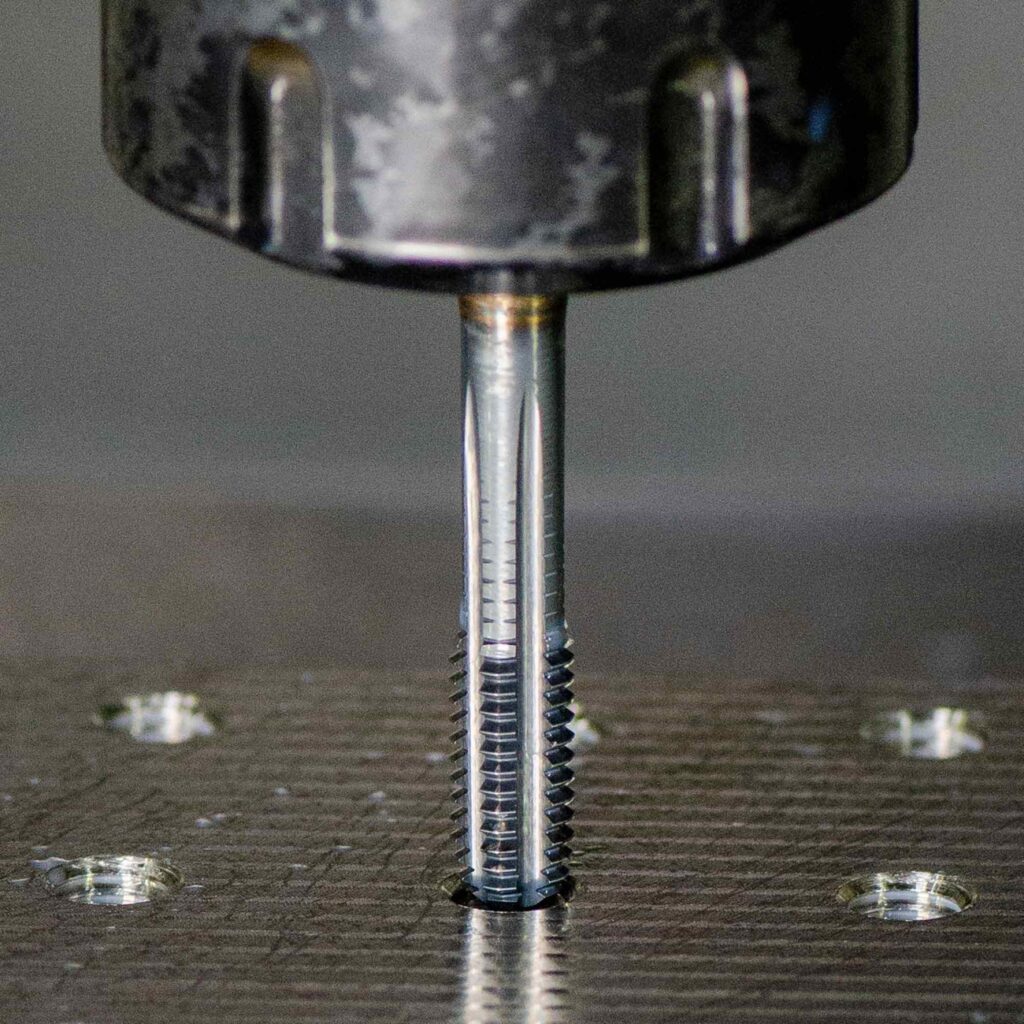

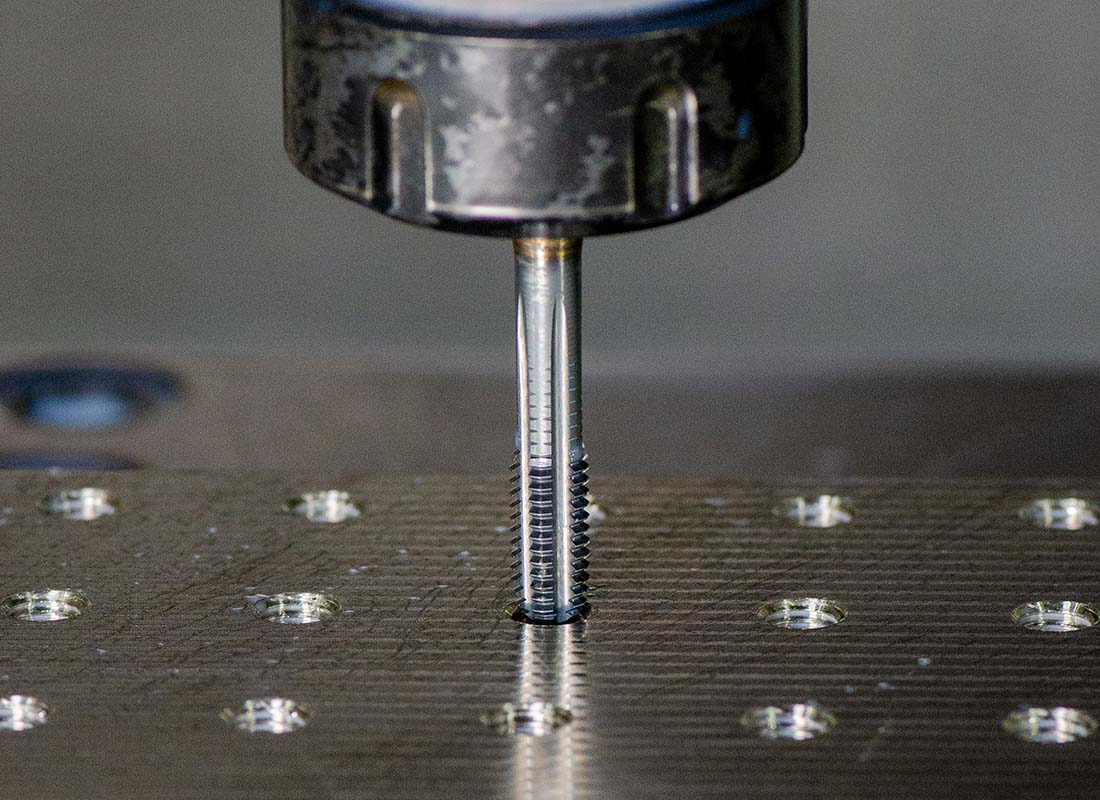

Water-soluble polymer-based cooling lubricants

are formulated to offer superior performance when a transparent product is required. Due to their molecular structure, these cooling lubricants significantly reduce friction and wear, extending tool life and improving operational safety in mechanical processes.

These cooling lubricants are ideal for applications requiring advanced protection against heat and high pressure.

The polymers provide a stable and durable lubricant film, which helps to maintain excellent lubricity, allowing swarf to settle quickly. The use of polymer-based lubricants ensures a safe working environment, reducing the chemical risk to operators and the environment.

Due to their unique composition, these lubricants offer a number of advantages that make them ideal for a wide range of industrial applications.

Understanding polymer-based lubricants

Polymer-based lubricants are formulated using synthetic polymers that give the end product superior properties compared to traditional lubricants. These polymers can be designed to have a variety of characteristics, such as increased heat resistance, improved chemical stability and reduced volatility. These properties make polymer-based lubricants particularly suitable for applications where operating conditions are extreme or where long lubricant life is required.

Applications and use in industrial contexts

In the context of machine shops, polymer-based lubricants are used in numerous applications. They are particularly effective in high-temperature systems, such as those found in engines and heavy machinery, where heat resistance is crucial. Furthermore, due to their chemical stability, these lubricants are ideal for environments where aggressive chemicals are present that could degrade conventional lubricants.

The use of polymer-based lubricants can also help reduce wear on mechanical components, extending equipment life and reducing maintenance costs. This is particularly beneficial in areas where downtime can result in significant losses.

Advantages of polymer-based lubricants

One of the main advantages of polymer-based lubricants is their ability to operate effectively over a wide temperature range. Unlike traditional lubricants, which can lose efficacy at extreme temperatures, polymer-based lubricants retain their lubricating properties, ensuring continuous protection of mechanical surfaces.

Furthermore, the reduced volatility of these lubricants means they evaporate less quickly, reducing the need for frequent reapplications and contributing to a more efficient use of resources. This not only reduces operating costs, but also has a positive impact on the environment, as less lubricant is dispersed into the environment.

Answers to frequently asked questions

One of the most common questions about polymer-based lubricants is whether they are compatible with existing systems. The answer is generally yes, as these lubricants are designed to be compatible with a wide range of materials and components. However, it is always advisable to consult the lubricant manufacturer to ensure that it is suitable for the specific application.

Another frequently asked question concerns the durability of these lubricants compared to conventional lubricants. Due to their advanced composition, polymer-based lubricants tend to last longer, reducing the frequency of replacements and improving overall operating efficiency.

Conclusions

In summary, polymer-based lubricants offer a number of significant benefits for machine shops and other industrial applications. Their ability to perform under extreme conditions, combined with increased durability and reduced volatility, makes them an excellent choice for those seeking to improve the efficiency and sustainability of their operations. As lubrication technologies continue to evolve, polymer-based lubricants represent the future of industrial lubrication, offering innovative solutions for the challenges of today and tomorrow.