Oil mist extractors

Oil mist aspirators are an essential component for modern machine shops, where air quality and work safety are top priorities. Read more

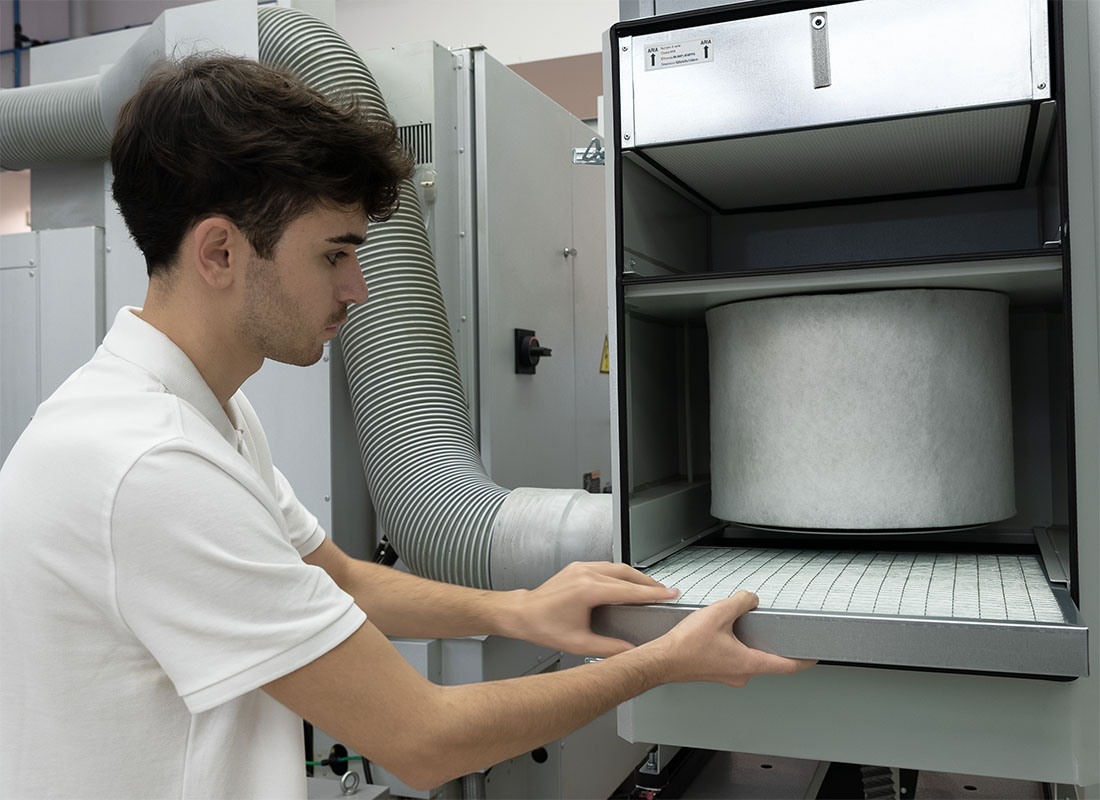

Oil mist extractors are devices designed to remove airborne oily particles generated by machining operations.

These systems improve the air quality in the working environment, reducing the exposure of operators to harmful vapours and contributing to a safer and healthier environment.

Using an oil mist extractor ensures effective control of indoor air pollution

preventing the accumulation of oily residues on machinery and surfaces. These devices reduce the risk of equipment malfunctioning, improving safety and the overall efficiency of the production process, as well as reducing heating and maintenance costs.

These devices are designed to remove airborne oil particles generated during machining processes such as turning, milling and grinding. The presence of oil mists not only compromises air quality, but can also pose a significant risk to workers' health and machine efficiency.

The crucial role of Oil mist aspirators

Oil mist aspirators are advanced devices that use a combination of technologies to capture and filter oil particles. These systems are key to maintaining a safe and clean working environment, minimising workers' exposure to potentially harmful substances. They also help prevent the accumulation of oily residue on machine and floor surfaces, reducing the risk of accidents and improving operational efficiency.

Advanced filtration technologies

Oil mist aspirators use various filtration technologies to ensure maximum efficiency. Of these, electrostatic filters and mechanical filters are the most common. Electrostatic filters use an electric field to attract and capture oil particles, while mechanical filters employ porous materials to trap particles. Some advanced systems combine both technologies to offer even more effective filtration.

Advantages of using Oil mist aspirators

The adoption of Oil mist aspirators offers several advantages for machine shops. Firstly, they improve air quality by reducing the concentration of oil particles and other pollutants. This not only protects workers' health, but also contributes to a more comfortable and productive working environment. In addition, reducing oil build-up on machine and floor surfaces decreases the risk of slips and falls, improving overall safety.

Energy efficiency and sustainability

Many modern Oil mist aspirators are designed to be energy efficient, reducing energy consumption and operating costs. In addition, the use of reusable filter materials and the ability to recycle captured oil help reduce the environmental impact of industrial operations. This makes Oil mist aspirators a sustainable choice for companies wishing to reduce their ecological footprint.

Frequently asked questions about Oil mist aspirators

One of the most common questions concerns the maintenance of Oil mist aspirators. It is essential to follow the manufacturer's recommendations for cleaning and filter replacement to ensure optimal operation. In addition, many people wonder about the average lifetime of an Oil mist aspirator. Although the lifetime may vary depending on the model and use, most devices are designed to last several years with proper maintenance.

Conclusions

Oil mist aspirators are indispensable tools for machine shops that want to ensure a safe and clean working environment. Thanks to their advanced filtration technologies, these devices offer an effective solution for reducing the presence of oil particles in the air, improving air quality and work safety. With proper maintenance, Oil mist aspirators can offer years of reliable service, helping to improve the operational efficiency and sustainability of industrial operations.