Industrial greases and multipurpose oils

Industrial Greases and Multipurpose Oils: Essential Solutions for Machine Maintenance

In industrial settings, choosing the right lubricants is crucial to ensure maximum efficiency and longevity of machinery. Read more

Industrial greases and multipurpose oils are formulated to provide reliable lubrication in various industrial applications.

These products reduce friction and wear on mechanical components, providing lasting protection even under high loads and extreme conditions, thereby improving efficiency and reducing downtime.

The use of high-quality industrial greases and multipurpose oils ensures the smooth operation of various types of equipment.

Their versatility makes them ideal for both specific lubrication and general applications, helping to extend the life of machinery, reduce maintenance costs and improve operational safety.

Industrial greases and multipurpose oils are among the most versatile and widely used products, as they provide reliable lubrication and wear protection across a broad range of applications. These lubricants help reduce friction, prevent corrosion, and extend equipment life, ultimately reducing maintenance costs and boosting productivity. In this article, we will explore the benefits of industrial greases and multipurpose oils and how to select the best products for your operational needs.

What Are Industrial Greases and Multipurpose Oils?

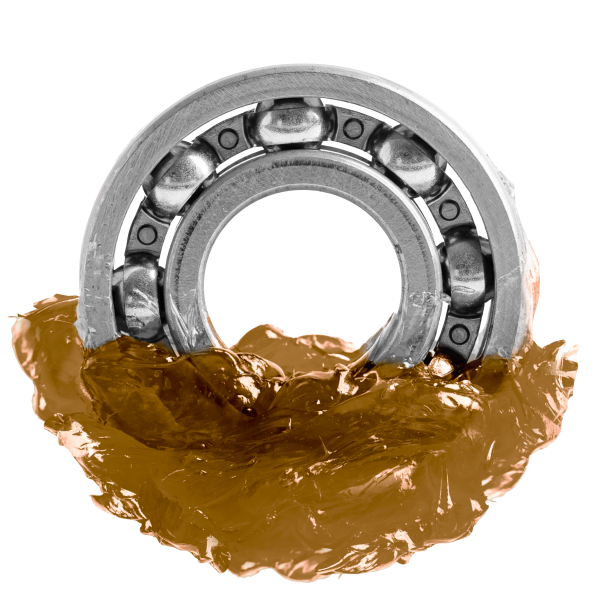

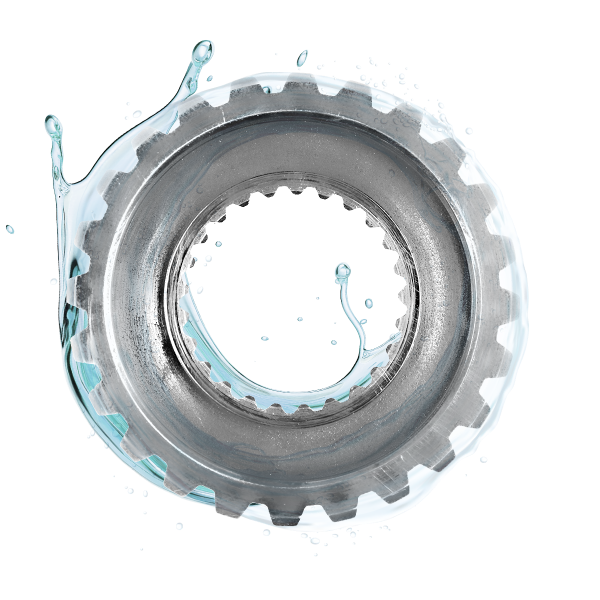

Industrial greases are semi-solid lubricants designed to adhere to surfaces even under high pressure or temperature, offering long-lasting protection against wear and corrosion. On the other hand, multipurpose oils are versatile fluid lubricants that can be used in various applications, from bearings to gears, providing effective lubrication under a wide range of operating conditions.

These lubricants are formulated to withstand a wide range of temperatures, loads, and work environments, making them an ideal choice for multiple industrial sectors. Whether for machine tools, production facilities, or agricultural equipment, industrial greases and multipurpose oils ensure optimal performance and simplified maintenance.

Benefits of Using Industrial Greases and Multipurpose Oils

Using industrial greases and multipurpose oils in industrial applications offers numerous benefits that can significantly improve the efficiency and longevity of equipment. The main benefits include:

Versatility: Greases and multipurpose oils can be used in various applications, reducing the need for specific products for each machine component.

Wear Protection: These lubricants form a protective barrier that reduces friction between moving surfaces, preventing premature wear of mechanical parts.

Corrosion Resistance: Due to their composition, greases and multipurpose oils offer protection against corrosion, particularly in humid or chemically aggressive environments.

Enhanced Energy Efficiency: By reducing friction, these lubricants improve the operational efficiency of machinery, helping to reduce energy consumption and optimise performance.

Reduced Maintenance Costs: Using high-quality lubricants like industrial greases and multipurpose oils can reduce the frequency of maintenance, improve equipment lifespan, and lower repair costs.

High-Pressure Industrial Greases

High-pressure industrial greases are formulated to withstand extreme operating conditions, where contact surfaces are subject to heavy loads. These greases contain additives that enhance the lubricant's ability to remain stable under pressure, preventing film breakdown and ensuring continuous protection. They are ideal for applications such as heavy bearings, gears, and equipment operating under challenging conditions.

Best Multipurpose Oils for Industrial Machinery

The best multipurpose oils for industrial machinery offer excellent lubrication across various conditions without the need to change products based on the application. These oils are designed for use in hydraulic systems, gears, bearings, and other mechanical components. Their ability to perform under a wide range of temperatures and loads makes them indispensable for the daily operations of many industries.

Greases and Oils for High-Temperature Applications

Some industrial equipment operates in environments with extremely high temperatures, where traditional lubricants may degrade or lose effectiveness. Greases and oils for high-temperature applications are formulated with special additives that maintain their thermal stability, ensuring continuous lubrication even under extreme heat conditions. These products are essential for industries such as steel manufacturing, glass production, and other applications that demand high performance at elevated temperatures.

How to Choose the Right Grease or Multipurpose Oil

Selecting the right industrial grease or multipurpose oil is essential to ensure maximum protection and performance for your equipment. Here are a few factors to consider when choosing the most suitable product:

Type of Application: It’s essential to consider the specific needs of the machine or plant. For example, high-speed bearings require a lubricant with different viscosity than low-speed gears.

Operating Conditions: Temperatures, loads, and the work environment affect the choice of lubricant. It’s crucial to select a product that can withstand the most challenging conditions, such as exposure to moisture, chemicals, or high temperatures.

Lubricant Longevity: Some greases and multipurpose oils are formulated for extended life, reducing the frequency of lubrication operations and enhancing maintenance efficiency.

Frequently Asked Questions About Industrial Greases and Multipurpose Oils

When should I choose a grease instead of an oil for my application?Grease is generally preferred for applications requiring long-lasting lubrication, where the product needs to stay in place, such as in bearings or linear guides. Oil, on the other hand, is ideal for systems requiring smoother lubrication, such as engines or transmissions.

Can industrial greases be used under all operating conditions?There are greases formulated for different operating conditions, such as high temperatures, high pressures, or corrosive environments. It is important to choose the right grease based on the specific needs of the application.

Can multipurpose oils be used on any industrial machine?Yes, multipurpose oils are designed to be versatile and can be used on various machines and components, provided they are suitable for the operating conditions and specifications of the machinery.

Conclusion

Industrial greases and multipurpose oils are essential tools for keeping industrial equipment running smoothly. They offer effective protection against wear, corrosion, and friction, while also improving energy efficiency and reducing maintenance costs. Investing in the right lubricants can make a significant difference in the productivity and longevity of your industrial machines, contributing to your company's long-term success.