Industrial Greases

In the world of machine shops, the importance of greases cannot be underestimated. Read more

-

LANDOIL lithium grease

LANDOIL lithium grease offers universality of use, mechanical stability and resistance to oxidation for reliable and long-lasting performance in every application. -

Multigrease MP LANDOIL grease

Multigrease MP LANDOIL grease offers universality of use, excellent mechanical stability and high ep characteristics for superior performance. -

Multigrease MP/R 00 LANDOIL grease

Multigrease MP/R 00 LANDOIL grease is designed for lubricating guides and slides, ensuring mechanical stability and excellent oxidation resistance.

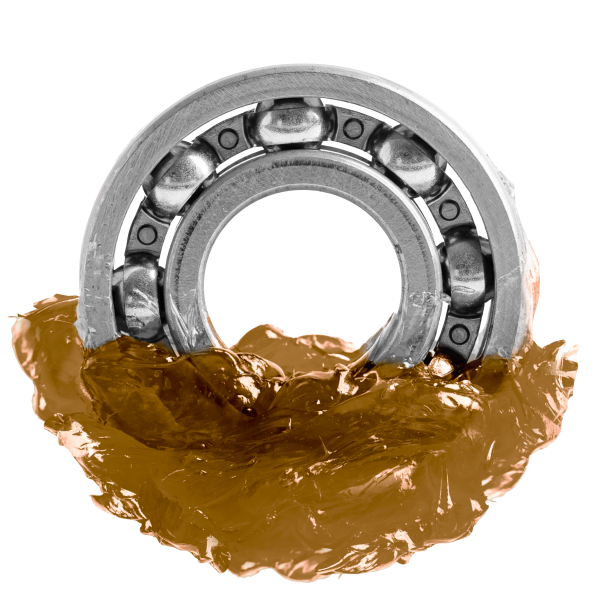

Industrial greases are semi-solid lubricants ideal for reducing friction between moving surfaces.

Due to their consistency, they adhere to surfaces providing long-lasting lubrication even under heavy loads or extreme temperatures, thus protecting equipment from wear and damage.

These lubricants are particularly effective for protecting bearings, gears and other mechanical components subject to prolonged stress.

Industrial greases resist washout and contamination, ensuring continuous and safe operation. Their application helps to reduce maintenance costs and improve operational safety.

These often overlooked compounds play a crucial role in ensuring the optimal functioning of the machines and tools used on a daily basis. In this in-depth look, we will explore in detail what greases are, what they are used for, how they are used and what benefits they offer. We will also answer some of the most frequently asked questions about their use.

Understanding fats: a technical overview

Fats are lubricating substances that occur in a semi-solid form at room temperature. They consist of a base oil, a thickener and various additives that enhance their properties. The base oil can be mineral, synthetic or vegetable, while the thickener is usually a metal soap, such as lithium or calcium. Additives, on the other hand, are designed to give the grease specific characteristics, such as water resistance, corrosion protection or the ability to operate at extreme temperatures.

The importance of greases in mechanical workshops

In machine shops, greases are essential for reducing friction between moving metal surfaces. This not only extends the service life of machines, but also improves operating efficiency. Correct application of greases can prevent premature component wear, reduce energy consumption and minimise the risk of mechanical failure.

Using greases: practical applications

The application of greases in machine shops varies depending on the specific requirements of machines and tools. Greases are used in bearings, gears, couplings and other moving parts. It is essential to choose the appropriate type of grease for each application, taking into account factors such as rotation speed, operating temperature and operating environment.

Advantages of using greases

The use of greases offers numerous advantages in machine shops. Firstly, greases provide long-lasting lubrication, reducing the need for frequent maintenance. In addition, due to their consistency, greases remain in place even under conditions of high pressure or vibration, providing continuous protection. Greases can also improve corrosion resistance, protecting metal surfaces from moisture and other corrosive agents.

Frequently asked questions on the use of greases

1. What is the difference between oil and grease?

Oils are fluids and are used in applications where continuous, fluid lubrication is required. Greases, being semi-solid, are ideal for applications where the lubricant needs to stay in place.

2. How do I choose the right grease for my machine?

The choice of grease depends on various factors, including the type of machine, operating conditions and the manufacturer's specifications. It is advisable to consult the machine manual or an expert to determine the most suitable grease.

3. How often should I apply grease?

The frequency of application depends on the use of the machine and the operating conditions. In general, it is important to follow the manufacturer's recommendations and monitor the condition of the grease regularly.

4. Can greases be mixed?

In general, mixing different greases is not recommended, as this can alter their properties and reduce the effectiveness of lubrication. If it is necessary to change grease types, it is important to clean the component thoroughly before applying the new grease.

5. What are the signs that grease needs to be reapplied?

Common signs include unusual noises, increased operating temperature and visible component wear. Regular inspection can help identify these signs early.

Conclusion: the strategic importance of fats

In conclusion, greases are a key element in the efficient and long-lasting operation of machines in machine shops. Their correct application and maintenance can make the difference between smooth operation and costly downtime. Investing in the right type of grease and training staff in its correct use can lead to significant savings in operating costs and an overall improvement in machine performance.