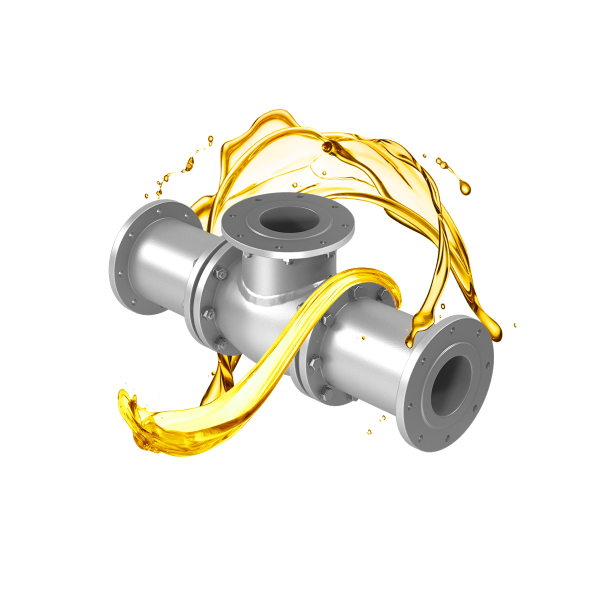

Hydraulic oils

Hydraulic oils are an essential element in the operation of machine shops and industries that rely on hydraulic systems for their daily operations. Read more

-

Hydraulic oil ester bases Abacus BIO LANDOIL

Abacus BIO LANDOIL ester-based hydraulic oil is biodegradable, ideal for environmentally friendly applications requiring high performance and sustainability. -

Mineral-based hydraulic oil Abacus HVI LANDOIL

Abacus HVI LANDOIL mineral-based hydraulic oil with a high viscosity index for optimal, long-lasting performance in hydraulic systems. -

Mineral-based hydraulic oil Abacus LANDOIL

Abacus LANDOIL mineral-based hydraulic oil offers an excellent natural viscosity index for superior and reliable performance in every application.

Hydraulic oils are essential fluids for the efficient operation of hydraulic systems

ensuring force transmission and lubrication of internal components. Formulated to withstand high operating pressures, these oils with high thermal stability protect against wear and prevent corrosion, ensuring consistent performance.

The use of high-quality hydraulic oils is critical to maintaining the efficiency of hydraulic systems

reducing downtime and maintenance costs. These oils offer advanced protection against foaming and deposit formation, improving operational safety and extending equipment life, even under extreme conditions.

These specialised fluids are designed to transmit power within hydraulic systems, ensuring efficient and reliable machine operation. In this in-depth look, we will explore in detail what hydraulic oils are, what they are used for, how they are used, the benefits of using them, and answer some of the most frequently asked questions on this topic.

What are hydraulic oils?

Hydraulic oils are fluids specifically formulated for use in hydraulic systems. These systems are widely used in a variety of industrial applications, including heavy machinery, agricultural equipment, construction vehicles and manufacturing plants. Hydraulic oils are designed to transmit power, lubricate moving components, reduce wear, and protect systems from corrosion.

The composition of hydraulic oils can vary, but generally includes a mineral or synthetic oil base, additives to improve lubrication properties, oxidation inhibitors and anti-wear agents. The choice of type of hydraulic oil depends on the specific requirements of the system in which it will be used, such as operating temperature, pressure and operating environment.

What are hydraulic oils used for?

Hydraulic oils perform several crucial functions within hydraulic systems. Their primary function is to transmit power. In hydraulic systems, power is transmitted through fluid, which is pumped through pipes and valves to drive hydraulic cylinders and motors. This process allows mechanical energy to be converted into hydraulic energy and vice versa, enabling the precise movement and control of machines.

In addition to power transmission, hydraulic oils play an essential role in the lubrication of moving components within the system. Lubrication reduces friction between moving parts, minimising wear and tear and extending equipment life. In addition, hydraulic oils help dissipate heat generated during operation, keeping operating temperatures within safe limits.

How are hydraulic oils used?

The correct use of hydraulic oils is crucial to ensure the efficient and safe operation of hydraulic systems. The choice of the appropriate hydraulic oil depends on several factors, including system specifications, environmental conditions and the equipment manufacturer's recommendations. It is important to follow the manufacturer's guidelines for selecting and replacing hydraulic oils to avoid performance problems and component damage.

Regular maintenance of hydraulic systems is essential to ensure that hydraulic oils remain clean and free of contaminants. Contamination by solid particles, water or other fluids can impair system performance and cause component damage. Therefore, it is important to regularly monitor the quality of the hydraulic oil and replace it according to the manufacturer's instructions.

Advantages of using hydraulic oils

The use of high-quality hydraulic oils offers numerous advantages for machine shops and industries that rely on hydraulic systems. One of the main advantages is the increase in operating efficiency. Well-formulated hydraulic oils reduce friction and wear, improving energy efficiency and reducing maintenance costs.

In addition, hydraulic oils protect system components from corrosion and oxidation, prolonging equipment life. Corrosion protection is particularly important in harsh operating environments, where exposure to moisture and chemicals can damage metal components.

Another significant advantage is the ability of hydraulic oils to operate over a wide temperature range. High-quality hydraulic oils maintain their lubrication and power transmission properties even at extreme temperatures, ensuring reliable operation in varying climatic conditions.

Frequently asked questions about hydraulic oils

1. What is the difference between mineral and synthetic hydraulic oils?

Mineral hydraulic oils are derived from petroleum and are generally cheaper, while synthetic oils are chemically formulated to offer superior performance in extreme conditions. The choice between the two depends on the specific needs of the system and operating conditions.

2. How often should I change the hydraulic oil?

The frequency of hydraulic oil change depends on the equipment manufacturer's recommendations and operating conditions. In general, it is advisable to regularly monitor the quality of the oil and replace it when necessary to maintain optimal system performance.

3. What happens if the hydraulic oil is contaminated?

Contaminated hydraulic oil can cause a number of problems, including accelerated component wear, reduced system efficiency and the risk of failure. It is important to monitor and maintain oil cleanliness to avoid these problems.

4. Can I mix hydraulic oils of different brands?

It is generally not recommended to mix hydraulic oils of different brands, as the formulations may vary and mixing could compromise system performance. It is preferable to use oils of the same brand and specification recommended by the manufacturer.

5. What are the signs of a problem with hydraulic oil?

Signs of a problem with the hydraulic oil can include unusual noises, increased operating temperature, reduced system performance and fluid leaks. If these signs are found, it is important to perform timely inspection and maintenance to identify and resolve the problem.

In conclusion, hydraulic oils are essential components for the efficient and reliable operation of hydraulic systems in machine shops and industries. The correct choice and use of hydraulic oils can improve operating efficiency, reduce maintenance costs and extend equipment life. With proper maintenance and attention to oil quality, companies can ensure optimal performance and reliability of their hydraulic systems.