General lubrication oils

General lubrication oils: an essential element for machine shops

In the world of mechanical workshops, lubrication is a crucial aspect that cannot be overlooked. Read more

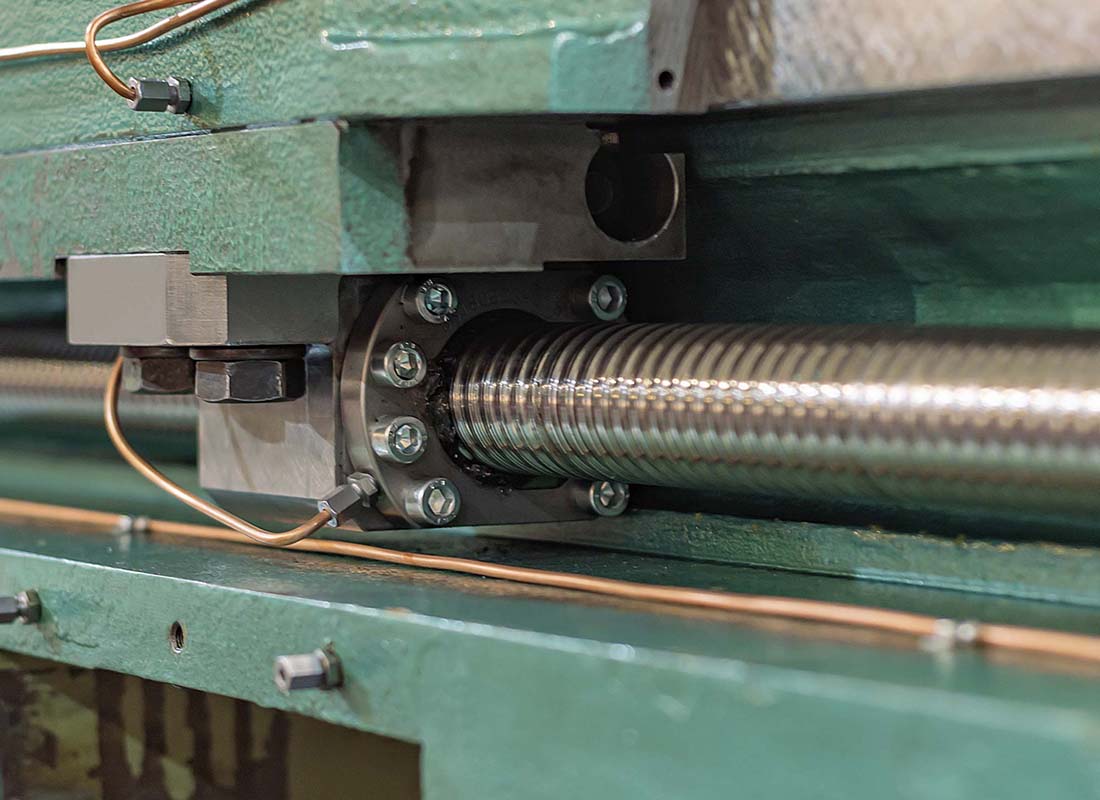

General lubrication oils are versatile fluids designed to provide effective lubrication in various disposable mechanical applications.

They offer good protection against wear and oxidation, reducing friction between moving surfaces and improving the operating efficiency of equipment.

Thanks to their composition, these oils ensure constant and long-lasting lubrication

protecting mechanical components from premature failure. General lubrication oils help maintain machinery in optimal condition, reducing maintenance costs and improving operational safety through their reliability and durability.

General lubrication oils play a vital role in ensuring the proper functioning of the machines and tools used on a daily basis. These oils are designed to reduce friction between moving surfaces, prevent wear and protect metal components from corrosion. In this in-depth look, we will explore in detail what general lubrication oils are, what they are used for, how they are used, and what benefits they offer.

What are general lubrication oils?

General lubrication oils are fluids specifically formulated to reduce friction and wear between moving metal surfaces. These oils are composed of a mineral or synthetic oil base, enriched with additives that enhance their lubricating properties. Additives may include anti-wear agents, antioxidants, corrosion inhibitors and cleaning agents. The choice of oil type depends on the specific needs of the application and operating conditions.

What are general lubrication oils used for?

General lubrication oils serve several purposes in machine shops. First, they reduce friction between metal surfaces, which helps prevent premature wear of components. This is especially important in machines that operate at high speeds or under heavy loads. In addition, lubricating oils help dissipate heat generated by friction, keeping operating temperatures within safe limits. They also protect metal components from corrosion, prolonging equipment life.

How are general lubrication oils used?

The application of general lubrication oils varies depending on the type of machine and operating conditions. In general, oil is applied directly to moving surfaces using automatic or manual lubrication systems. It is important to follow the manufacturer's recommendations regarding the amount and frequency of oil application. Excessive or insufficient application can compromise the effectiveness of lubrication and cause damage to components.

Benefits of using general lubrication oils

The use of general lubrication oils offers several advantages for machine shops. First of all, it helps reduce maintenance costs, as proper lubrication prevents wear and premature component failure. It also improves the operating efficiency of machines, reducing energy consumption and increasing productivity. High-quality lubricating oils can also improve the precision and reliability of equipment, ensuring more accurate machining results.

Frequently asked questions about general lubrication oils

1. What is the difference between mineral oils and synthetic oils?

Mineral oils are derived from crude oil and are generally cheaper. Synthetic oils, on the other hand, are chemically produced and offer superior performance in terms of thermal stability and oxidation resistance.

2. How do I choose the right oil for my application?

The choice of oil depends on the specific needs of the application, such as operating temperature, load and speed. It is important to consult the manufacturer's recommendations and, if necessary, seek expert advice.

3. How often should I change the lubricating oil?

The frequency of oil change depends on the operating conditions and the type of machine. In general, it is advisable to follow the manufacturer's recommendations and monitor the condition of the oil regularly.

4. Can I mix oils of different brands?

Mixing oils of different brands is not recommended as the additives may not be compatible with each other. This could impair oil performance and cause component damage.

5. What are the signs of inadequate lubrication?

Signs of inadequate lubrication include abnormal noises, increased operating temperature, premature component wear and oil leakage. If these problems are found, it is important to take early action to avoid greater damage.

In conclusion, general lubrication oils are an essential element in the proper functioning of machine shops. The correct choice and application of these oils can make all the difference in terms of operational efficiency, equipment life and maintenance costs. Investing in high-quality lubrication oils and following best lubrication practices is crucial to ensure the long-term success of mechanical operations.