Gear oils

Gear oils: an essential element for machine shops

In the world of machine shops, the choice of lubricants plays a crucial role in ensuring the optimal operation of machines and systems. Read more

Gear oils are formulated to provide optimal lubrication, reducing friction and wear between gear components.

These oils offer superior resistance to high pressures and heavy loads, protecting metal surfaces from corrosion and damage and improving the reliability of mechanical systems.

Ideal for harsh industrial environments and operating conditions, gear oils ensure long equipment life and reduced maintenance costs.

Their advanced formulation prevents the formation of deposits and foam, improving efficiency and contributing to a safer, malfunction-free working environment.

Among the various types of lubricants, gear oils occupy a prominent position due to their ability to reduce friction, prevent wear and improve operational efficiency. In this in-depth look, we will explore in detail what gear oils are, what they are used for, how they are used and what benefits they offer. We will also answer some of the most frequently asked questions on this topic.

What are gear oils?

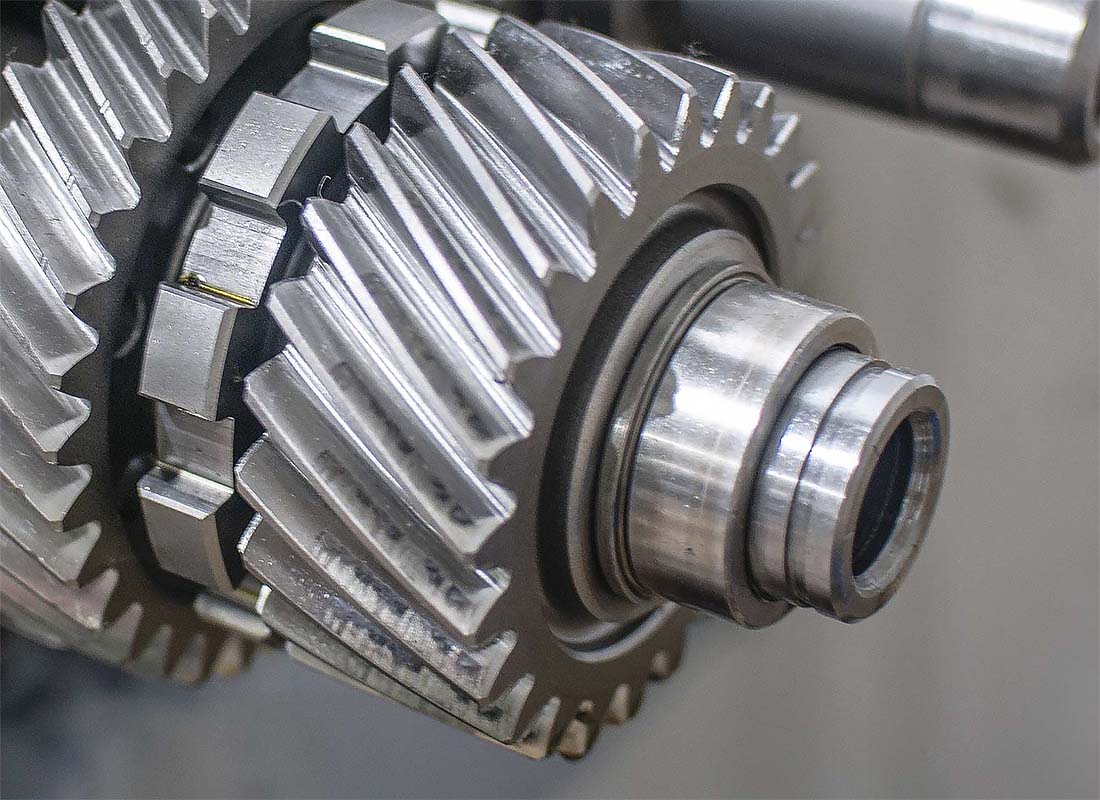

Gear oils are lubricants specifically formulated to protect and improve the performance of gears in a wide range of industrial applications. These oils are designed to withstand extreme operating conditions, such as high pressures, high temperatures and heavy loads. Their chemical composition is designed to provide a durable lubricating film that reduces friction between moving metal surfaces, thus minimising wear and extending the life of gears.

What are gear oils used for?

Gear oils are primarily used to lubricate and protect gears in machinery and industrial plants. Their main function is to reduce friction between contacting metal surfaces, which helps prevent gear wear and damage. In addition, these oils help dissipate heat generated during operation, thus keeping operating temperatures within safe limits. Another important role of gear oils is to protect metal surfaces from corrosion and rusting, thus ensuring longer life and reliability of equipment.

How are gear oils used?

The correct use of gear oils is crucial to ensure maximum performance and protection. First of all, it is essential to select the right oil according to the specific needs of the application. This includes consideration of factors such as gear type, operating conditions, temperatures and loads. Once the appropriate oil has been chosen, it is important to follow the manufacturer's recommendations regarding application quantity and frequency. In general, gear oils are applied via central lubrication systems or manually, depending on the size and complexity of the system.

Benefits of using gear oils

The use of high-quality gear oils offers numerous benefits for machine shops and industries that depend on complex machinery. Some of the main benefits include:

1. Reduced wear: Gear oils form a protective film that reduces friction and wear between metal surfaces, thus extending the life of gears.

2. Improved operating efficiency: Proper lubrication reduces energy losses due to friction, improving overall system efficiency.

3. Corrosion protection: Additives in gear oils help prevent corrosion and rust formation, protecting metal surfaces from oxidation.

4. Heat dissipation: Gear oils help dissipate heat generated during operation, keeping operating temperatures within safe limits and preventing overheating.

5. Reduced maintenance costs: Effective lubrication reduces the need for frequent maintenance, thereby lowering operating costs and increasing productivity.

Frequently asked questions about gear oils

1. What is the difference between mineral and synthetic gear oils?

Mineral gear oils are derived from crude oil and are generally cheaper, but can have a shorter service life than synthetic oils. Synthetic oils, on the other hand, are chemically formulated to offer superior performance in terms of oxidation resistance, thermal stability and wear protection. The choice between mineral and synthetic oils depends on the specific needs of the application and the available budget.

2. How do I choose the right gear oil?

Choosing the right gear oil depends on several factors, including the type of gears, operating conditions, temperatures and loads. It is important to consult the equipment manufacturer's recommendations and consider the technical specifications of the oil, such as viscosity, wear protection and corrosion resistance.

3. How often should gear oils be changed?

The frequency with which gear oils should be changed depends on the operating conditions and the manufacturer's recommendations. In general, it is advisable to regularly monitor the condition of the oil through periodic analysis and replace it when it shows signs of degradation, such as loss of viscosity or the presence of contaminants.

4. What are the signs of a gear lubrication problem?

Signs of a gear lubrication problem can include abnormal noises, increased operating temperatures, excessive vibration and visible wear on metal surfaces. If these symptoms are present, it is important to take early action to identify and resolve the cause of the problem.

5. Is it possible to mix gear oils of different brands?

In general, it is not recommended to mix gear oils of different brands, as the chemical formulations may vary and adversely affect the performance of the lubricant. If it is necessary to change brands, it is advisable to thoroughly flush the system before introducing the new oil.

In conclusion, gear oils are an essential component for the efficient and reliable operation of industrial machines. The correct choice and use of these lubricants can make all the difference in terms of performance, durability and operating costs. Machine shops and industries that invest in high-quality gear oils can benefit from increased productivity, reduced downtime and extended equipment life.