Ester based neat cutting and grinding oils

Foreign-based neat cutting oils are an essential component of modern machining. Read more

-

Neat cutting oil Mirzan EP LANDOIL

Mirzan EP LANDOIL neat cutting oil with high flash point, low smoke, high tool yield, oxidation stability, does not stain yellow alloys. -

Neat cutting oil Mirzan LANDOIL

Mirzan LANDOIL neat cutting oil with high flash point, low smoke, high tool yield, very stable to oxidation, does not stain yellow alloys. -

Neat cutting oil Mirzan S LANDOIL

Mirzan S LANDOIL neat cutting oil With high flash point, low smoke, high tool yield, oxidation stability and resistance to ageing. -

Neat cutting oil Tap Fluid AL LANDOIL

Chlorine- and mineral oil-free Tap Fluid AL LANDOIL neat cutting oil, suitable for drilling, threading, milling and tapping on aluminium alloys. -

Neat cutting oil Tap Fluid BLUE LANDOIL

Tap Fluid BLUE LANDOIL neat cutting oil with high lubricating power, chlorine-free, suitable for drilling, threading, milling and tapping.

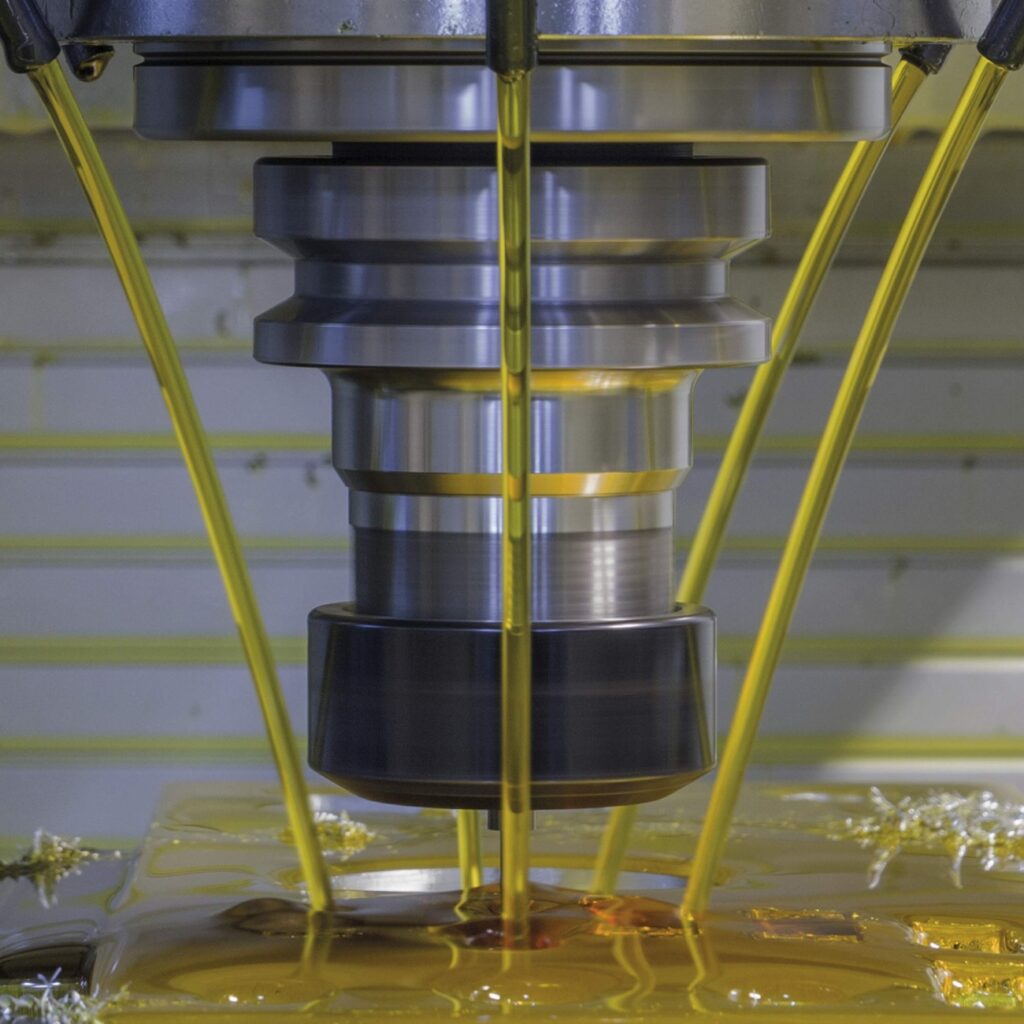

Ester-based neat oils are fluids used in machining processes to lubricate and cool tools.

These oils, free of mineral components, provide high lubricity and very high thermal and chemical stability, reducing risks for the operator and improving the safety of the working environment.

Due to their composition, ester-based neat cutting oils offer excellent lubricating properties

that reduce tool wear and increase tool life. The use of these oils not only improves the quality of machining, but also contributes to the reduction of maintenance costs while maintaining a high level of operational safety.

These fluids, essential for the proper functioning of machine tools, offer a number of advantages that make them indispensable in many industrial applications. In this in-depth look, we will explore in detail what neat cutting oils with foreign bases are, how they are used, the benefits they offer and answer some of the most frequently asked questions on this topic.

Introduction to neat cutting oils with ester bases

Ester-based neat cutting oils are lubricating fluids mainly used in metal cutting and machining operations. Unlike emulsifiable oils, which are mixed with water, whole oils are used in their pure form. Ester bases, derived from natural or synthetic sources, give these oils unique properties that make them particularly suitable for high-performance applications.

Properties and composition of ester-based neat cutting oils

The composition of neat cutting oils with ester bases is designed to ensure high thermal stability and low volatility. Due to their chemical structure, ester bases offer excellent lubrication and low residue formation. These characteristics are essential for keeping cutting surfaces clean and extending tool life.

Advantages of using ester-based neat cutting oils

One of the main advantages of ester-based neat cutting oils is their ability to reduce friction between the tool and workpiece. This not only improves the quality of the surface finish, but also reduces tool wear, leading to lower operating costs. In addition, their thermal stability allows them to maintain lower machining temperatures, preventing overheating and deformation of machined parts.

Industrial applications of neat cutting oils with ester bases

Foreign-based neat cutting oils are used in a wide range of industrial applications. They are particularly popular in high-speed machining and operations requiring high precision, such as turning, milling and drilling. Their ability to provide constant lubrication and reduce heat build-up makes them ideal for use in advanced machine tools.

Environmental and safety considerations

An important aspect to consider when using neat cutting oils with ester bases is their environmental impact. As ester bases are often derived from renewable sources, they offer a more sustainable alternative to traditional mineral oils. Furthermore, their biodegradability reduces the risk of pollution in the event of accidental spills. However, it is crucial to follow safety guidelines when handling and disposing of these fluids to ensure a safe working environment.

Frequently asked questions about ester-based neat cutting oils

1. What is the difference between whole oils and emulsifiable oils?

Whole oils are used in their pure form, while emulsifiable oils are mixed with water to form an emulsion. Whole oils offer superior lubrication and are ideal for high-performance applications.

2. Are ester-based neat cutting oils suitable for all machining operations?

Although they are extremely versatile, it is important to select the right oil according to the type of machining and workpiece material. Always consult the manufacturer's specifications for best results.

3. How should neat cutting oils with foreign bases be disposed of?

Oils must be disposed of in accordance with local and national regulations. It is advisable to contact a company specialised in the disposal of industrial waste to ensure a safe and environmentally friendly process.

Conclusions

Foreign-based neat cutting oils are an advanced solution for the needs of modern machine shops. Thanks to their unique properties, they offer excellent lubrication, reduce tool wear and improve machining quality. Choosing to use these oils not only helps optimise production processes, but also represents a step towards more sustainable industrial practices. With proper selection and handling, foreign-based neat cutting oils can become a valuable ally for any industry operator.